The Rise and Impact of Chain Block Manufacturers in Industrial Applications

Chain blocks, also known as chain hoists or block and tackle systems, play a crucial role in various industrial applications by providing efficient lifting solutions. These ingenious devices utilize a system of pulleys and chains to lift heavy objects with minimal physical effort. As industries continue to evolve, the demand for reliable and sophisticated lifting equipment has surged, leading to a significant rise in chain block manufacturers around the world.

Understanding Chain Blocks

A chain block consists of a chain, a lifting mechanism, and a frame that houses the pulleys. The operator pulls on one end of the chain, which passes through the pulleys to lift the load on the other end. The design of chain blocks allows them to be used in various settings, from construction sites to warehouses and manufacturing plants. They are essential for lifting heavy machinery, moving goods, and facilitating construction tasks.

These devices can be classified into manual and powered chain blocks. Manual chain blocks require human effort to operate, making them cost-effective and easy to maintain. On the other hand, powered chain blocks, which use electrical or hydraulic systems for operation, are ideal for heavy-duty applications, where efficiency and speed are critical.

The Role of Chain Block Manufacturers

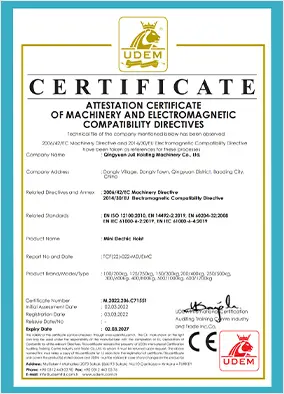

Chain block manufacturers are pivotal in ensuring that industries have access to high-quality lifting equipment. They undertake rigorous design and testing processes to develop products that meet safety standards and can withstand the rigors of heavy lifting. Renowned manufacturers emphasize safety features in their designs, incorporating overload protection, automatic brakes, and durable materials to prevent accidents and injuries in the workplace.

The manufacturing process of chain blocks typically involves selecting suitable materials such as high-strength steel for the chains and robust frameworks to ensure durability. Advanced technology and precision engineering are employed to guarantee that each component of the chain block functions seamlessly, contributing to the overall efficiency of the device.

Market Trends and Innovations

As the industrial landscape evolves, chain block manufacturers are adapting to meet the changing needs of the market. There is an increasing focus on automation and smart technology, leading to the development of digitally controlled chain blocks. These innovative systems enable remote operation, real-time monitoring, and data analytics, significantly enhancing safety and productivity in industrial environments.

Moreover, sustainability is becoming a critical consideration for manufacturers. Many companies are exploring eco-friendly materials and manufacturing methods to reduce their environmental impact. This shift towards sustainability not only aligns with global trends but also appeals to consumers seeking to partner with environmentally responsible suppliers.

Global Industry Landscape

The chain block manufacturing industry is witnessing substantial growth, driven by increased industrialization and infrastructure development across the globe. Emerging economies, particularly in Asia-Pacific, are at the forefront of this expansion. Countries like China and India are not only major consumers of chain blocks but also significant producers, contributing to the global supply chain.

The competitive landscape includes a mix of established companies and new entrants. Established manufacturers often have the advantage of brand recognition and extensive distribution networks. In contrast, new manufacturers are leveraging innovation and niche markets to carve out their space in the industry.

Conclusion

In conclusion, chain block manufacturers are integral to the modern industrial ecosystem. Their commitment to safety, quality, and innovation ensures that industries can operate efficiently while minimizing risks associated with heavy lifting. As technology continues to advance, the next generation of chain blocks promises even greater capabilities, supporting industries in their quest for efficiency, sustainability, and safety.

The rising demand for chain blocks and the increasing complexity of industrial applications will likely drive further innovation and competition among manufacturers. Ultimately, as industries evolve, chain blocks will remain a fundamental part of the infrastructure that supports economic growth and progress in the industrial sector. Whether through manual or powered solutions, these devices are undeniably vital for the safe and efficient handling of heavy loads.