In the burgeoning landscape of industrial components, the role of a chain block manufacturer cannot be overstated. As industries increasingly demand precision, reliability, and efficiency, manufacturers specializing in chain blocks are stepping up to deliver unparalleled solutions. The journey of a chain block manufacturer from raw material to market-ready product is a testament to engineering excellence and industry expertise.

Understanding the intricacies of chain block manufacturing begins with acknowledging the foundational role these components play in material handling across diverse sectors. From construction sites to manufacturing plants, chain blocks offer a lifting solution that is indispensable for both safety and efficiency. The process of crafting a chain block involves meticulous material selection, precision engineering, and rigorous testing, all aimed at achieving optimal performance and longevity.

Expert manufacturers prioritize the selection of high-quality materials. Typically, the process begins with sourcing robust metals, such as heat-treated steel, which promises durability and strength. The chosen materials are then subjected to a series of treatments and checks to ensure they meet the industry's stringent standards. This initial phase is crucial as the material's integrity forms the basis for the entire product's performance.

The design and engineering phase is where a manufacturer’s expertise truly shines. Utilizing cutting-edge technology, including CAD software, manufacturers design chain blocks that are not only functional but also ergonomic. Each component, from the chain to the hook, is meticulously designed to maximize strength while minimizing weight, ensuring ease of use without compromising on durability. This phase often involves simulations and prototypes, allowing engineers to refine the mechanics before full-scale production begins.

Manufacturers who are leaders in the field often hold certifications that attest to their adherence to international standards. These certifications are not merely bureaucratic hurdles but serve as benchmarks of quality and reliability. They encompass aspects such as load testing, material safety, and operation efficiency. By achieving these certifications, a manufacturer signals their commitment to excellence and safety, instilling confidence among their clients.

A crucial aspect of chain block manufacturing is the assembly process, which demands a high level of precision and expertise. Skilled technicians, leveraging their extensive knowledge, carefully assemble each unit, ensuring that all components function in harmony. The alignment, tension, and fit of each component are tested meticulously, and any potential issues are addressed immediately, reducing the chance of malfunction or failure in the field.

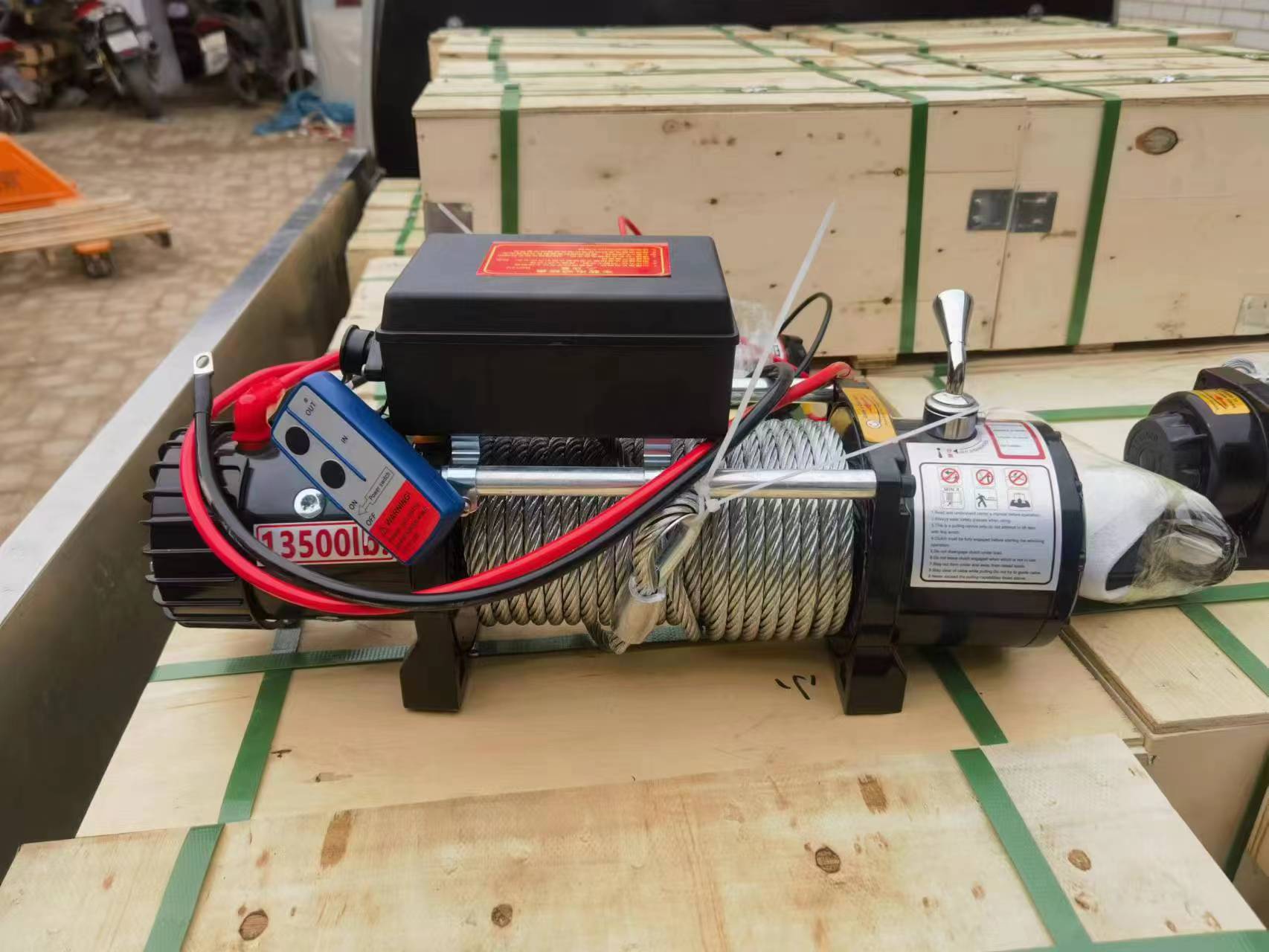

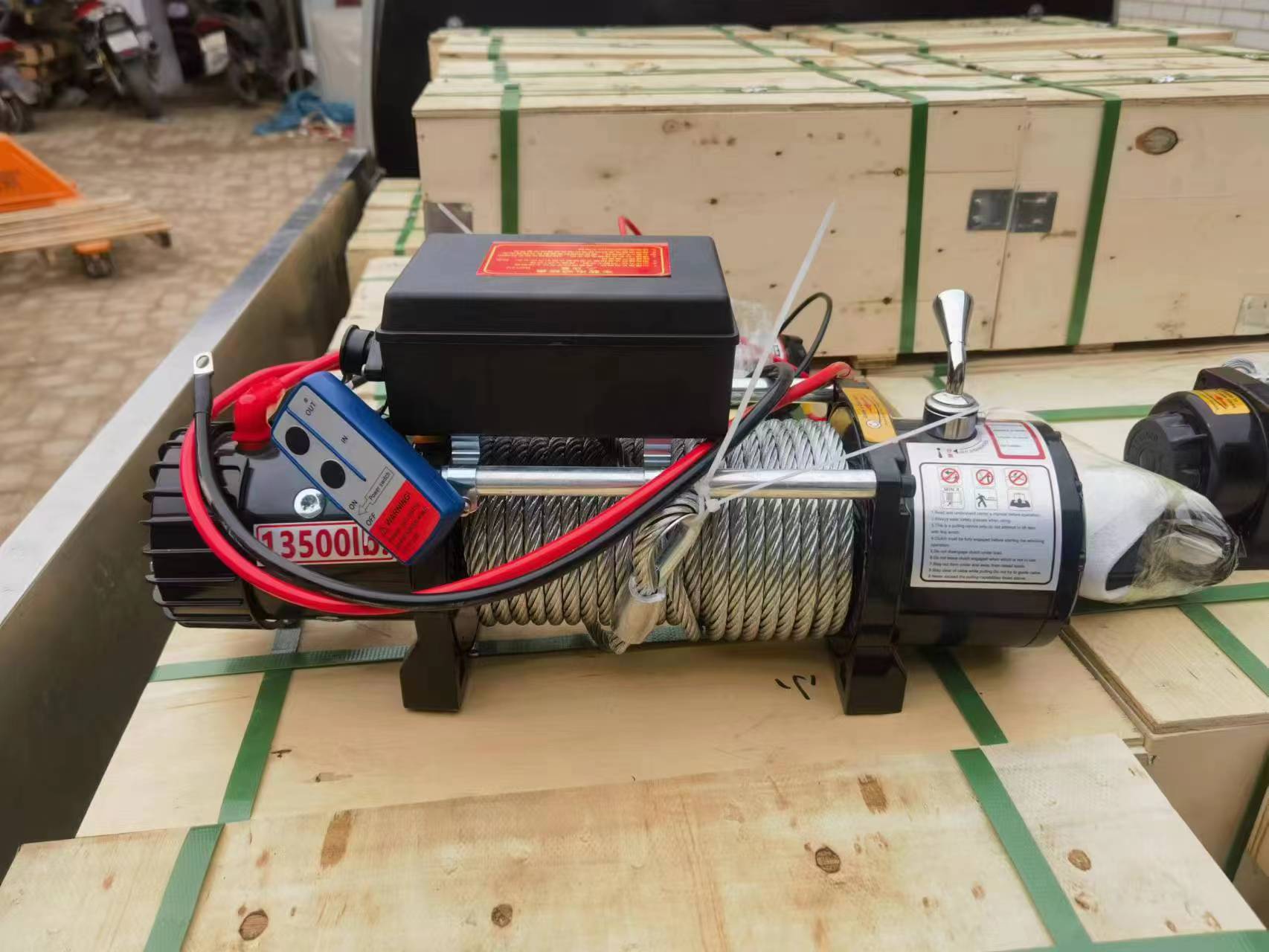

chain block manufacturer

Beyond manufacturing, top-tier chain block manufacturers engage in continuous quality control and product testing. This includes regular stress tests and load-bearing trials, which simulate real-world conditions to ensure the chain blocks can withstand the demands they are marketed for. The feedback loop from quality control to production is vital, enabling manufacturers to make iterative improvements based on data and performance metrics.

Innovation is another hallmark of leading chain block manufacturers. The evolution of material handling demands innovative solutions that are both efficient and adaptable. Manufacturers invest heavily in research and development to create products that not only meet today's needs but also anticipate future industrial requirements. This proactive approach ensures they remain at the forefront of technological advancements, offering products that give industries a competitive edge.

Moreover, a reputable chain block manufacturer understands the importance of customer education and support. They offer comprehensive guides and training materials to ensure customers have the knowledge to use their products safely and effectively. Additionally, robust after-sales support further establishes trust and reliability, as clients have the assurance of expert assistance should any issues arise post-purchase.

Finally,

the pursuit of sustainability is reshaping the manufacturing landscape. Environmentally conscious manufacturers are exploring eco-friendly materials and processes, aiming to reduce their carbon footprint while maintaining product quality. This commitment to sustainability not only meets the growing consumer demand for green products but also reflects a broader responsibility towards environmental stewardship.

In conclusion, the expertise of a chain block manufacturer is evident in every stage of the production process—from material selection and engineering design to assembly and customer support. Their dedication to quality, innovation, and sustainability ensures that they stand as authoritative figures in the industry, providing reliable solutions that empower businesses worldwide.