Understanding Hand Chain Blocks A Comprehensive Guide

Hand chain blocks, also known as hand chain hoists or manual chain hoists, are essential tools in various industries, from construction to manufacturing, where lifting heavy loads is a frequent necessity. Understanding how these devices function and the various applications they serve is crucial for anyone involved in heavy lifting tasks.

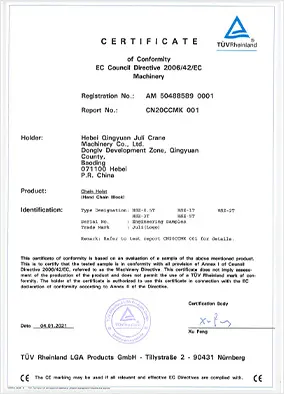

What is a Hand Chain Block?

A hand chain block is a mechanical device that allows users to lift and lower heavy loads using a manual chain. This tool employs a block and tackle mechanism, which combines wheels and a looped chain to provide a mechanical advantage. The user pulls on the chain, which engages the hoist mechanism to lift or lower the load with relative ease.

Typically, hand chain blocks are designed for portability, making them ideal for work sites where electrical power is unavailable. They come in various lifting capacities, usually ranging from 0.5 to 20 tons, and are made from durable materials such as steel or high-strength aluminum for robust performance.

How Do Hand Chain Blocks Work?

The inner workings of a hand chain block involve several key components the chain, hook, gears, and load chain. When the user pulls the hand chain (the chain loop), it rotates the gears inside the block. This rotation moves the load chain, thereby lifting or lowering the load attached to the hook.

The mechanical advantage is perhaps the most significant feature of hand chain blocks; for every pull of the hand chain, the load rises significantly higher due to the reduction in force required to lift the weight. This allows a user to lift heavy items without needing heavy machinery or electrical power.

Applications of Hand Chain Blocks

Hand chain blocks are versatile and can be used across numerous applications, including

1. Construction Sites Hand chain blocks are commonly used to hoist materials such as beams and concrete blocks, making them invaluable on construction sites. 2. Warehousing In warehouses, these hoists assist in moving and stacking heavy products and supplies, improving efficiency in inventory management.

3. Maintenance and Repair These devices are also utilized in maintenance tasks, particularly in lifting machinery for repairs in factories and workshops.

4. Marine Applications Hand chain blocks are frequently used in marine settings to hoist and lower equipment on boats or ships, where electricity may not be accessible.

5. Automotive Industry In garages and automotive shops, hand chain blocks help lift engines and body parts to facilitate repairs and maintenance.

Safety Considerations

While hand chain blocks are effective lifting tools, safety measures must be followed to prevent accidents. It is essential to inspect the equipment regularly for wear and tear, including the chain and hooks, to ensure safe operation. Additionally, proper training on using these devices is critical to avoid injuries. Users should be aware of the load limits and ensure that the load is securely attached before lifting.

Conclusion

Hand chain blocks are an invaluable resource in various industries, offering an effective, efficient, and versatile solution for lifting heavy loads. Understanding their operation, applications, and safety measures can greatly enhance productivity and safety in workplaces that require heavy lifting. As industries continue to evolve, the hand chain block remains a fundamental tool that showcases the importance of manual handling solutions in modern mechanical tasks.