Understanding Hand Chain Blocks Their Importance and Applications

In the realm of material handling and lifting equipment, hand chain blocks, also known as hand chain hoists, play a crucial role. These devices are designed to lift and lower heavy loads through a chain mechanism operated manually. This article delves into the features, advantages, applications, and safety considerations surrounding hand chain blocks.

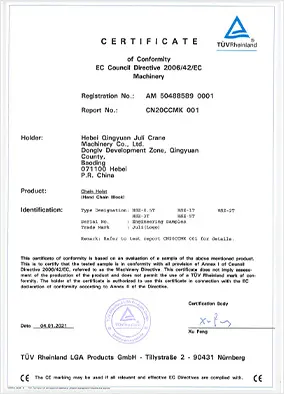

What is a Hand Chain Block?

A hand chain block consists of a load chain, a hand chain, a hoisting mechanism, and a hook. The primary function is to lift materials by utilizing mechanical advantage. When the user pulls the hand chain, it engages a system of gears that raises the load chain, consequently lifting the attached load. Most hand chain blocks are compact and portable, making them suitable for various environments ranging from construction sites to workshops.

Key Features and Advantages

1. Manual Operation One of the most significant advantages of hand chain blocks is that they require no power supply. This is particularly beneficial in locations where electricity is unavailable or impractical. The manual operation allows for greater control over the load being lifted or lowered.

2. Safety Mechanisms Most models come with built-in safety features such as overload protection and limit stops, which prevent the block from being operated beyond its capacity. This design minimizes the risk of accidents, ensuring safer operations.

3. Durability Hand chain blocks are typically constructed from high-strength materials like steel or alloy, providing robustness and resilience. With proper maintenance, they can have a long operational life, which reduces the need for frequent replacements.

4. Cost-Effective Compared to electric hoists, hand chain blocks are generally more affordable. Their lower initial cost, coupled with minimal maintenance requirements, makes them a cost-effective solution for lifting applications.

Applications of Hand Chain Blocks

Hand chain blocks are incredibly versatile and find applications in numerous fields

- Construction They are widely used on construction sites for lifting heavy building materials, tools, and machinery. Their portability allows workers to move them to different locations as required.

- Manufacturing In factories, hand chain blocks assist in assembling large components or moving heavy machinery for maintenance and repair.

- Warehousing They are ideal for lifting pallets, boxes, and other items in warehouses to optimize space and streamline operations.

- Automotive Mechanics often use hand chain blocks to lift engines or heavy automotive parts, facilitating repairs and replacements.

- Theatrical Productions In the world of performing arts, hand chain blocks are used to lift and lower stage props, lighting, and equipment, contributing to the seamless execution of productions.

Safety Considerations

While hand chain blocks offer many advantages, safety should always be a top priority. Here are some considerations

1. Load Ratings It is crucial to know the load capacity of the hand chain block and never exceed it. Overloading can lead to equipment failure and accidents.

2. Proper Training Operators should be adequately trained in the use of hand chain blocks, understanding their functionality and safety features to prevent mishandling.

3. Regular Inspections Periodic inspections and maintenance ensure that the block’s components are in good condition. Any wear or damage should be addressed immediately to maintain safety.

4. Environment When using a hand chain block, it’s essential to assess the work environment. Factors such as uneven surfaces, weather conditions, and nearby hazards can affect safety.

Conclusion

Hand chain blocks are invaluable tools that contribute to the efficient lifting and handling of heavy loads across various industries. Their manual operation, safety features, and versatility make them a preferred choice for many. However, proper usage and safety precautions are paramount to ensure a safe working environment. By understanding these devices and implementing best practices, users can enhance operational efficiency while mitigating the risks associated with heavy lifting.