Lifting Equipment A Critical Component in Modern Industry

Lifting equipment plays a crucial role across various industries, facilitating the movement, lifting, and positioning of heavy loads safely and efficiently. From construction sites to manufacturing plants, the utilization of lifting devices ensures that tasks are completed efficiently while minimizing the risk of injury to workers and damage to products.

One of the most common types of lifting equipment is the crane. Cranes come in various forms, including mobile cranes, tower cranes, and overhead cranes, each serving different purposes based on the specific needs of a project. For instance, tower cranes are often employed in large construction projects, reaching great heights and capable of lifting substantial weights. Their design allows them to rotate and extend, offering exceptional versatility on job sites.

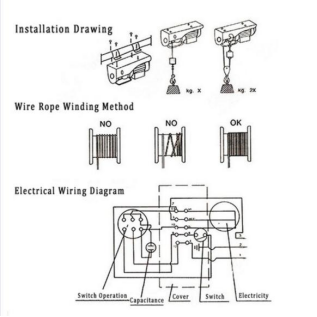

Another vital category of lifting equipment is hoists. These devices are used for lifting or lowering loads using a drum or lift-wheel around which a rope or chain wraps. Hoists can be manually operated or powered, with electric and pneumatic options available. They are indispensable in settings where heavy objects must be moved vertically, such as in warehouses, workshops, and assembly lines.

Forklifts are also widely recognized as essential lifting equipment in many businesses

. These powered industrial trucks are designed to lift and transport materials over short distances, making them invaluable in logistics and warehousing operations. The ability to maneuver in tight spaces while carrying significant weight enhances productivity and ensures smooth operations in various sectors.Safety is a paramount concern when it comes to lifting equipment. To mitigate risks, operators must be properly trained and certified to use these machines. Regular maintenance and inspections are also essential to ensure that lifting equipment meets safety standards and operates efficiently. Equipment that shows signs of wear and tear should be immediately taken out of service to prevent accidents.

In addition to enhancing operational efficiency and safety, advancements in technology have led to the development of smart lifting equipment. Incorporating sensors and IoT technology, these modern devices offer real-time data on load weights, environmental conditions, and equipment health, further improving safety and operational effectiveness.

In conclusion, lifting equipment is an integral part of modern industry, shaping the way heavy loads are handled across various sectors. As technology continues to evolve, the capabilities and efficiency of these machines will only improve, contributing to safer and more productive work environments. Emphasizing safety, training, and technology integration ensures that lifting equipment can meet the demands of an ever-changing industrial landscape.