In the industrial and manufacturing sectors, the requirement for reliable lifting equipment is indisputable. Businesses continually seek tools that offer efficiency, safety, and cost-effectiveness. A 1.5 ton chain block is one such vital piece of equipment, designed for lifting and maneuvering heavy loads with ease. Many factors influence the purchase decision, especially the price of a 1.

5 ton chain block, driving the importance of understanding these elements to make informed choices.

Understanding the Pricing Strategy

The price of a 1.5 ton chain block can fluctuate based on several core factors, including brand reputation, quality of materials, load capacity, and additional features such as safety mechanisms. Established brands often command higher prices due to their proven track record, durability, and safety assurances. Investing in a high-quality chain block can yield long-term savings by reducing maintenance costs and downtime associated with equipment failure.

Material Quality and Its Implications

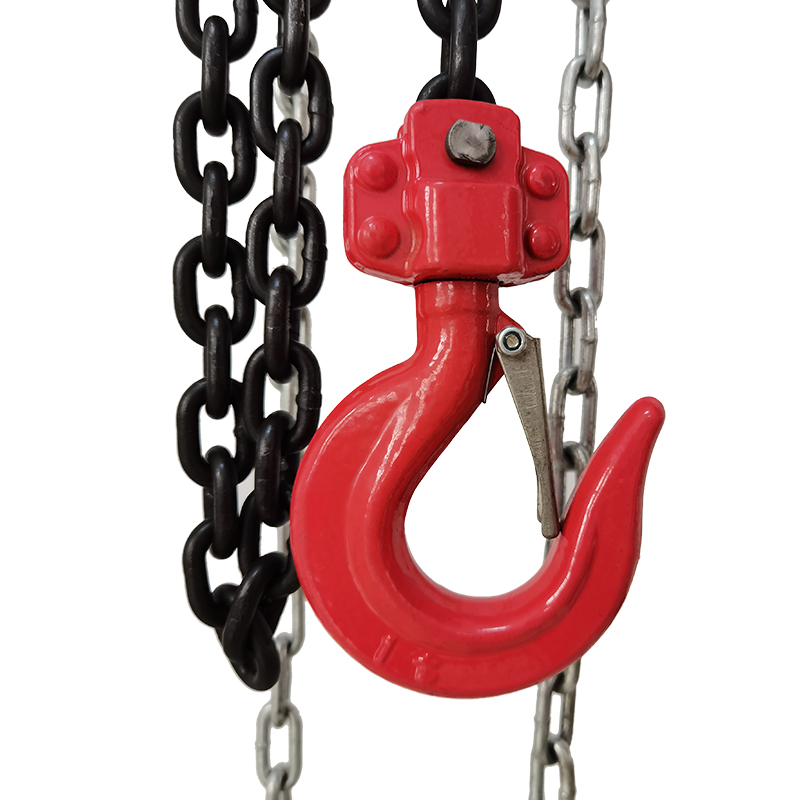

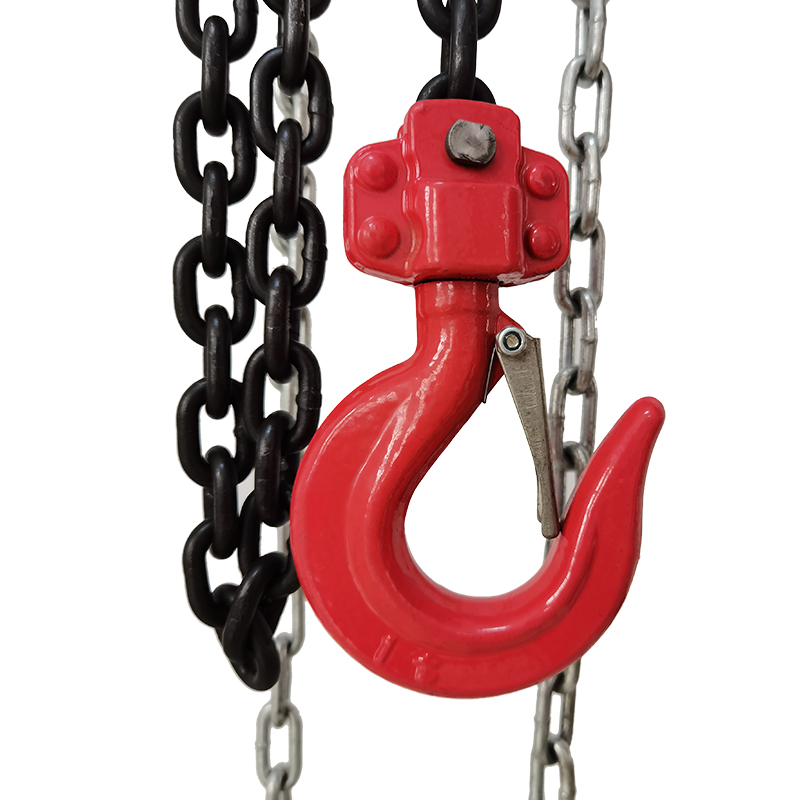

Materials used in manufacturing significantly affect the pricing. Chain blocks constructed from high-grade alloy steel tend to be more expensive due to their robustness and long lifetime. Such materials offer enhanced resistance against corrosion and wear, essential for ensuring operator safety and maintaining peak performance over prolonged periods. While cheaper alternatives are available, they may sacrifice durability and safety, which could lead to higher costs over time.

Safety and Compliance Standards

When it comes to lifting heavy loads, safety is paramount. Chain blocks that adhere to international safety standards generally come at a premium price. These certifications ensure the equipment has undergone rigorous testing and meets specific safety criteria, minimizing risks of operational failures. Price may not always reflect safety compliance; thus, buyers should verify certifications independently to ensure the equipment aligns with industry safety protocols.

Technological Integration

Modern chain blocks may also feature advanced technological integrations, such as load limit indicators and fail-safe brakes, which enhance operational safety and precision. These features tend to raise the price but provide significant value, especially in high-stakes environments where precision and safety can prevent accidents and enhance workflow efficiency.

1.5 ton chain block price

After-Sales Support and Warranty

The level of after-sales support and the warranty offered can influence the price. Companies offering extended warranty periods and comprehensive customer service usually have slightly higher prices. However, this added cost provides peace of mind, ensuring that any defects or operational issues can be swiftly addressed, reducing potential downtime and additional expenses.

Market Trends and Competitive Pricing

Market demand and competitive pricing strategies also affect the cost. Periodic fluctuations in the economy, changes in import tariffs, and emerging market trends can cause variances in price. Keeping abreast of market conditions and purchasing during promotional periods or from direct manufacturers can result in significant savings.

Comparative Analysis

Engaging in a comparative analysis between different products and manufacturers is vital. Online reviews and industry forums can offer insights into user experiences, highlighting the balance between cost and performance. Cross-referencing these reviews with official product specifications ensures that buyers are not only investing in a cost-effective solution but also in a product endorsed by user satisfaction and industry recognition.

In summary, when contemplating the purchase of a 1.5 ton chain block, it is crucial to evaluate not just the upfront cost but the value offered in terms of material quality, safety standards, technological features, and support services. Prioritizing long-term efficiency and safety over short-term savings is a strategic approach that will result in operational excellence and enhanced trustworthiness within industrial applications. This informed decision-making process will ultimately contribute to a safer and more productive workplace, validating the investment made in reliable lifting equipment.