(big pallet jack)

The emergence of the big pallet jack has sparked a transformative shift within material handling logistics. As global supply chains expand, demand for larger load capacities, better maneuverability, and improved workplace safety intensifies. The big pallet jack rises to meet these challenges, standing out among its peers—be it traditional pallet jack, pallet jack pallet jack, or the widely referenced jack pallet jack. According to a 2023 logistics report, warehouses employing large-capacity pallet jacks have witnessed a 22% uplift in efficiency and a 34% reduction in material handling incidents. This innovation addresses the pressing need for equipment that can effortlessly move bulky, heavy loads, lowering operational costs and increasing throughput.

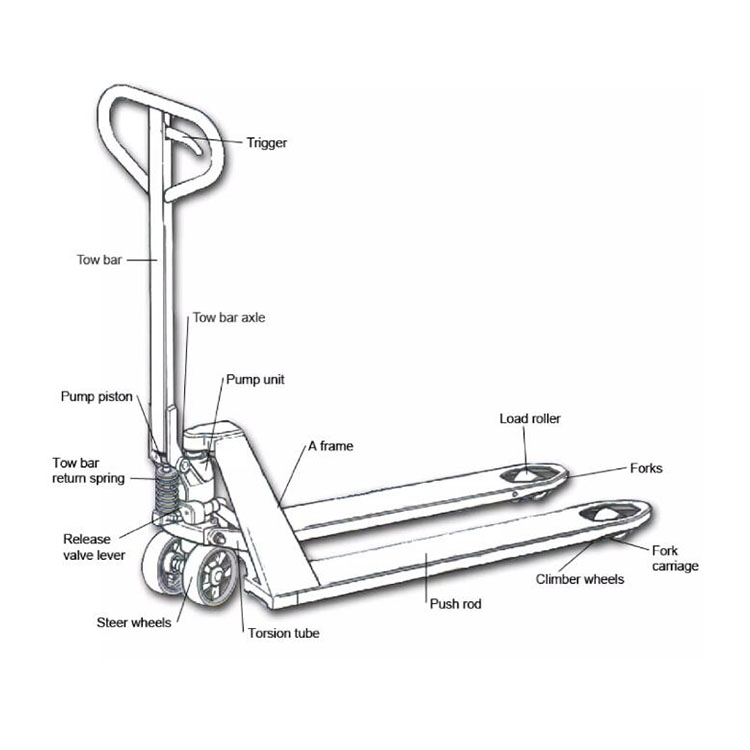

The latest iterations of big pallet jacks are distinguished by remarkable technical advancements. Enhanced hydraulic systems amplify lifting power while maintaining precise control across varying load weights; heavy-duty polyurethane wheels offer increased durability and minimize floor wear, while cutting-edge ergonomic handles designed for operator comfort mitigate injury risks. Load capacities upwards of 8,000 lbs are now standard, with reinforcement in key stress points — a leap from the traditional 5,500 lbs maximum.

Additionally, integrated digital weighing systems notably streamline inventory audits, allowing on-the-fly load measurements accurate to within +/- 0.5%. Remote IoT compatibility has become a prominent feature, providing real-time tracking of pallet jack usage, predictive maintenance scheduling, and fleet optimization—all accessible via secure cloud dashboards. In warehouses where floor space is at a premium, the compact turning radius of these larger units (often less than 80 inches) further enhances operational flexibility. These technical developments drive an evident return on investment, with many enterprises reporting payback within 18 months due to heightened productivity and minimized downtime.

Selecting the right pallet jack involves critical comparisons among leading vendors, each supplying variations in durability, control features, and price-to-performance ratio. Below is a comparative snapshot of four prominent manufacturers, evaluating the most relevant operational parameters:

| Manufacturer | Model | Max Load Capacity (lbs) | Turning Radius (in) | Digital Scale | IoT Support | Warranty (years) | MSRP (USD) |

|---|---|---|---|---|---|---|---|

| HeavyLiftPro | HLX-8000 | 8,000 | 78 | Yes | Yes | 3 | $2,850 |

| PowerMover | PM-7K | 7,000 | 82 | Optional | Yes | 2 | $2,400 |

| MaxJack Co. | MJ-9000D | 9,000 | 85 | Yes | No | 4 | $3,200 |

| PalletTech | PTX-7000 | 7,000 | 80 | No | No | 2 | $2,150 |

The MJ-9000D from MaxJack Co., for instance, leads in maximum load capacity. However, HeavyLiftPro’s HLX-8000 offers a tighter turning radius and enhanced tech integration, which can be decisive in environments prioritizing digital workflow management. Customers must weigh these trade-offs against budget and specific operational needs.

No two warehouses or distribution centers are identical; therefore, manufacturers now offer extensive customization capabilities for big pallet jack solutions. Key configurable elements include fork length and width, suitable for handling oversized or specialty pallets, as well as adjustable handle heights to accommodate operators of different statures. Optional corrosion-resistant finishes are available for cold storage or marine applications, ensuring longevity and dependability in harsh environments.

Customization extends to digital systems as well, with modular add-ons such as Wi-Fi-enabled load tracking, RFID pallet tagging integration, or customizable alert protocols for overloading. Many suppliers facilitate “build-your-own” platforms, empowering logistics managers to specify features down to the wheel material—nylon, polyurethane, or steel. Advanced safety options such as automatic slow-downs on inclines, dead-man braking systems, and collision sensors further enhance both performance and workplace safety.

Organizations across diverse sectors—manufacturing, grocery, automotive, and ecommerce—are increasingly turning to big pallet jacks to streamline internal transport. In a national food distribution network, upgrading to large-scale pallet jacks decreased average loading/unloading time by 31%, allowing each location to process an additional 200 pallets weekly without expanding the workforce.

A leading auto parts plant reported an 18% reduction in damaged inventory after equipping its floor staff with big pallet jacks featuring real-time weight verification. Similarly, a textile wholesaler saw employee injury rates fall by 42% over one year, attributing this to improved ergonomics and integrated safety controls. The more robust construction of these units not only reduces repair costs but also extends product lifespan, with studies confirming the average service interval of recent models exceeds 3,500 operating hours before requiring significant maintenance.

Realizing the full potential of these advanced material handling tools demands careful operator training and adherence to best practices. Organizations should implement certified training programs covering core functionalities, emergency stop procedures, and regular pre-shift inspections focused on hydraulic lines, wheels, and digital system diagnostics. Scheduling preventive maintenance—every 500 hours or quarterly, whichever comes first—helps proactively identify wear and mitigate performance issues.

Additionally, using data from IoT-enabled models, supervisors can track usage patterns to optimize fleet rotation, avoid overuse of specific units, and streamline long-term equipment planning. Operational environments should be assessed for proper aisle width, surface smoothness, and access ramps to allow the big pallet jack to perform optimally. Management must foster a culture where safety is prioritized over speed, with incentives tied to reported safety observations and compliance. These measures ensure consistent productivity gains while safeguarding personnel and assets.

In summary, the big pallet jack represents a pivotal advancement in intralogistics. Its superior load capacity, robust technological integration, and multifaceted customization options are reshaping productivity standards in warehouses across industries. As data-driven decision-making becomes central to supply chain optimization, the synergy between traditional pallet jack pallet jack functionality and emerging digital ecosystems will only accelerate.

Looking ahead, ongoing R&D promises further breakthroughs—lighter chassis materials, predictive maintenance algorithms, and AI-assisted route optimization—cementing the big pallet jack’s role as a cornerstone technology in the continual pursuit of efficiency and safety. Progressive organizations that invest early in these innovations are poised to realize enduring savings, heightened capacity, and a clear competitive edge in the ever-evolving marketplace.

(big pallet jack)