Understanding Hand Chain Blocks Essential Tools for Lifting and Material Handling

In the world of industrial lifting and material handling, efficiency and safety are paramount. One of the essential tools that facilities rely on for lifting heavy loads is the hand chain block. This mechanical device plays a crucial role in various industries, including construction, manufacturing, and warehousing. This article will explore what hand chain blocks are, how they work, their benefits, and their applications.

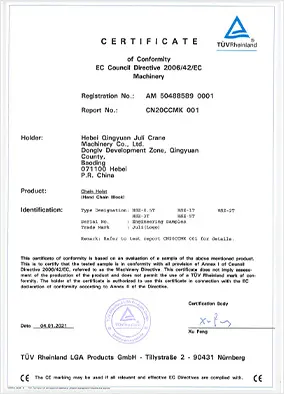

What is a Hand Chain Block?

A hand chain block, also known as a manual chain hoist, is a type of mechanical device used for lifting or lowering heavy objects. It consists of a chain wheel, a load hook, and two chains the lifting chain and the hand chain. The load hook is attached to the object being lifted, while the hand chain is used to operate the hoist manually. The lifting mechanism is powered by human effort, making it an accessible and cost-effective solution for various lifting tasks.

How Do Hand Chain Blocks Work?

Operating a hand chain block is straightforward. When the user pulls on the hand chain, it engages the gear mechanism inside the hoist, which in turn lifts the load attached to the hook. The system is designed to reduce the force needed to raise heavy objects, making it an efficient tool for lifting. The hand chain is looped around a series of gears that amplify the pulling force, allowing the operator to lift significantly heavier weights than they could manually.

Hand chain blocks come in various weight capacities, typically ranging from a few hundred pounds to several tons, allowing them to be utilized in different lifting applications. The mechanical advantage provided by the gear system ensures that users can lift heavy loads safely and with minimal physical strain.

Benefits of Hand Chain Blocks

1. Cost-Effective One of the primary advantages of hand chain blocks is their affordability compared to powered lifting equipment. They do not require electricity or batteries, making them an economical choice for many businesses.

2. Portability Hand chain blocks are typically lightweight and compact, making them easy to transport and store. This portability is especially beneficial for jobs that require lifting in various locations.

3. Ease of Use With a simple design, hand chain blocks are user-friendly. They can be operated by almost anyone with minimal training, reducing the need for specialized personnel.

4. Safety When used correctly, hand chain blocks can safely lift heavy loads with minimal risk. Most models come with safety features, such as overload protection and lower chain slack management, to enhance operational safety.

5. Versatility Hand chain blocks can be used in numerous applications, including construction sites, warehouses, and workshops. They are effective for lifting items such as machinery, beams, and heavy pallets.

Applications of Hand Chain Blocks

The versatility of hand chain blocks makes them suitable for a wide range of applications. In construction, they are often used to lift and position heavy construction materials, such as steel beams or concrete blocks. In warehouses, they facilitate the movement of pallets and heavy goods, streamlining operations and improving efficiency. Additionally, factories utilize hand chain blocks for assembly lines and maintenance tasks that require lifting heavy components.

Conclusion

Hand chain blocks are invaluable tools in the lifting and material handling industry. Their affordability, portability, ease of use, and versatility make them essential for many different applications. As industries continue to prioritize safety and efficiency, the hand chain block remains a go-to solution for overcoming the challenges associated with lifting heavy loads. Whether on a construction site or in a manufacturing facility, these mechanical devices play a crucial role in ensuring that operations run smoothly and safely.