The global material handling industry is undergoing significant transformation, driven by advancements in automation, ergonomics, and sustainability. Central to this evolution are the hand pallet jack manufacturers, who continuously innovate to meet diverse logistical demands. These manufacturers play a pivotal role in equipping warehouses, factories, and distribution centers with essential tools for efficient and safe load transportation. Modern hand pallet trucks are no longer just basic lifting devices; they incorporate sophisticated hydraulic systems, durable materials, and ergonomic designs to minimize operator fatigue and maximize productivity. The market trend indicates a growing demand for specialized units capable of handling unique load types, operating in challenging environments, and integrating with broader supply chain management systems. This focus on tailored solutions and robust construction is what sets leading manufacturers apart in a competitive landscape, ensuring that businesses can rely on their equipment for consistent, long-term performance across various industrial sectors.

Beyond basic functionality, contemporary needs emphasize higher load capacities, enhanced maneuverability, and extended operational lifespans. As businesses strive for operational excellence, the selection of a reliable hand pallet jack manufacturers becomes a critical strategic decision. They provide the foundational equipment for goods movement, from raw materials to finished products, influencing the overall efficiency and safety of internal logistics. The shift towards more ergonomic designs, for instance, directly reduces the risk of workplace injuries, contributing to a healthier and more productive workforce. Furthermore, the integration of advanced manufacturing techniques and rigorous quality control protocols ensures that each hand pallet truck meets stringent international standards, providing users with equipment that is not only robust but also compliant with safety regulations. This commitment to quality and innovation underpins the reputation of top-tier hand pallet jack manufacturers globally.

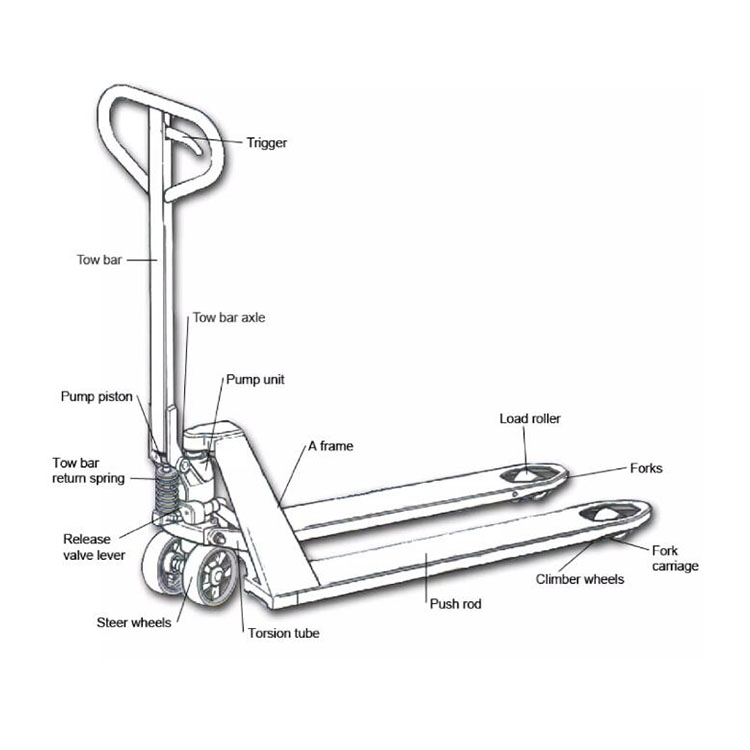

The Hand Pallet Truck - CBY exemplifies precision engineering tailored for demanding industrial applications. As a leading product from one of the most reputable hand pallet jack manufacturers, the CBY model integrates a robust hydraulic system, high-strength steel construction, and an ergonomic handle design for superior control and reduced operator strain. Its meticulously designed chassis ensures exceptional stability even under maximum load, making it ideal for continuous, heavy-duty operations. Key technical specifications include a lifting capacity often ranging from 2,500 kg to 3,000 kg, fork lengths typically between 1150 mm and 1220 mm, and a lowered fork height of approximately 85 mm, allowing for easy entry into various pallet types. The use of high-quality polyurethane or nylon wheels provides excellent maneuverability and floor protection, adapting seamlessly to diverse surface conditions, from smooth warehouse floors to rougher industrial settings.

The hydraulic system of the Hand Pallet Truck - CBY, a hallmark of advanced hydraulic hand pallet truck design, is engineered for smooth, reliable lifting and lowering, minimizing impact on the load and ensuring operator safety. It features an integrated pump design that is virtually leak-proof, reducing maintenance requirements and enhancing overall longevity. This design philosophy aligns with the stringent quality standards upheld by top hand pallet jack manufacturers, focusing on long-term durability and consistent performance in challenging environments. The CBY model's resilient paint finish provides superior corrosion resistance, crucial for applications in humid or chemically exposed settings, further extending its operational life and maintaining its aesthetic integrity over years of use. This attention to both internal mechanics and external protection makes the Hand Pallet Truck - CBY a cost-effective and dependable solution for material handling needs.

The manufacturing of high-quality hand pallet jacks involves a sophisticated multi-stage process, starting with the selection of premium-grade materials. Reputable hand pallet jack manufacturers typically utilize high-tensile steel for the frame and forks, ensuring maximum structural integrity and load-bearing capability. The process often begins with precision cutting and shaping of steel sheets, followed by advanced forming techniques like cold bending to achieve the desired fork profile. The hydraulic pump housing, a critical component of any hydraulic hand pallet truck, is often made from robust cast iron or forged steel to withstand immense pressure and ensure leak-free operation. Welding is performed using robotic systems or highly skilled technicians to ensure strong, consistent seams, crucial for the overall durability and safety of the unit.

Subsequent stages involve meticulous surface preparation and painting, often employing powder coating technology for superior chip and corrosion resistance, essential for longevity in harsh industrial environments such as petrochemical plants, metallurgical facilities, or water treatment plants where exposure to chemicals or moisture is common. CNC machining is extensively used for critical components like shafts, pins, and valve bodies to achieve micron-level precision, directly impacting the smooth operation and extended lifespan of the hand pallet truck. Every step of the manufacturing process adheres to rigorous international quality management standards, including ISO 9001, and products often comply with ANSI B56.10 safety standards for industrial trucks. Comprehensive testing, including overload testing, fatigue testing of the frame and hydraulic system, and functionality checks, ensures that each unit leaving the factory meets or exceeds industry benchmarks for reliability and performance. This commitment to stringent detection standards and quality control allows for an expected product lifespan of 5-10 years, depending on usage intensity and maintenance.

The versatility of the hand pallet truck makes it indispensable across a vast array of industries and application scenarios. From small retail outlets to large-scale manufacturing facilities, these robust units facilitate the seamless movement of goods, optimizing logistics and enhancing operational efficiency. In warehouses, they are the backbone of receiving, storage, and dispatch operations, allowing workers to quickly and safely relocate palletized inventory. Manufacturing plants utilize them to transport raw materials to production lines and move finished goods to staging areas. Within the logistics and distribution sector, hand pallet jack manufacturers provide solutions that are crucial for loading and unloading trucks, streamlining cross-docking operations, and preparing orders for shipment.

Specific advantages of using quality hydraulic hand pallet truck units in typical scenarios include their ability to operate in confined spaces where forklifts cannot, their low maintenance requirements, and their cost-effectiveness. In industries like pharmaceuticals or food and beverage, specialized stainless steel versions offered by certain hand pallet jack manufacturers ensure hygiene and corrosion resistance. For example, a major food processing plant reported a 15% reduction in manual handling injuries and a 10% increase in material flow efficiency after implementing an updated fleet of ergonomic hand pallet jacks. This direct impact on both safety and productivity underscores the critical role these seemingly simple machines play in complex industrial ecosystems. Their inherent energy efficiency, requiring no fuel or electricity for basic operation, also contributes to reduced operational costs and a lower carbon footprint, aligning with modern sustainability goals.

Choosing the right hand pallet truck involves evaluating several key technical parameters and understanding the differentiating factors between various hand pallet jack manufacturers. Beyond the primary considerations of load capacity and fork dimensions, factors such as lift height, turning radius, and wheel material significantly impact usability and suitability for specific applications. Load capacity, typically ranging from 2,000 kg to 5,000 kg, is paramount. Fork length (e.g., 800mm to 1500mm) and width (e.g., 550mm to 685mm) must match common pallet sizes.

| Parameter | Standard Manual Pallet Jack | Rough Terrain Pallet Jack | Scissor Lift Pallet Jack |

|---|---|---|---|

| Load Capacity | 2000-3000 kg | 1000-2000 kg | 800-1500 kg |

| Fork Length | 1150-1220 mm | 800-1200 mm | 1150 mm |

| Max Lift Height | 180-200 mm | 200-300 mm | 800 mm |

| Wheel Material | PU/Nylon | Rubber/Pneumatic | PU/Nylon |

| Applications | Warehouses, Retail, Factories | Construction Sites, Nurseries, Farms | Workbenches, Assembly Lines |

Beyond these standard models, leading hand pallet jack manufacturers often provide extensive customization options. This includes specialized fork dimensions for non-standard pallets, alternative wheel materials for specific floor types (e.g., anti-static for electronics, non-marking for clean rooms), galvanized or stainless steel constructions for corrosive or sanitary environments, and integrated weighing scales for immediate load measurement. A reputable manufacturer, like the producer of the CBY model, often has years of service experience and a track record of successful partnerships, evidenced by industry certifications such as CE, GS, or ETL, which further assure product quality and compliance. Tailored solutions ensure that businesses acquire equipment perfectly matched to their operational workflow, maximizing return on investment and ensuring long-term satisfaction.

Building trust with B2B clients extends beyond product quality; it encompasses comprehensive support, transparent processes, and clear communication. Reliable hand pallet jack manufacturers prioritize customer satisfaction through robust after-sales services and clear commitments. Understanding common concerns can help in the decision-making process.

As leading hand pallet jack manufacturers, we understand the importance of timely delivery for your operational continuity. Standard delivery times for in-stock models typically range from 7-14 business days, depending on destination and order size. Custom orders may require longer lead times, which will be clearly communicated during the quotation process. All products, including the Hand Pallet Truck - CBY, come with a comprehensive warranty against manufacturing defects, typically ranging from 1 to 2 years for major components and 6 months for wear parts. This commitment underscores our confidence in the quality and durability of our products, providing peace of mind to our clients.

Our dedication to customer satisfaction extends through the entire product lifecycle. We offer dedicated technical support, spare parts availability, and a responsive customer service team ready to assist with any inquiries, from product selection to troubleshooting and maintenance advice. Our global network of service partners ensures prompt and efficient support wherever your operations are located. This comprehensive support structure ensures that your investment in equipment from reliable hand pallet jack manufacturers remains productive and efficient for years to come.

The landscape of material handling is dynamic, requiring robust, efficient, and reliable equipment that can withstand the rigors of industrial operations. Choosing among the multitude of hand pallet jack manufacturers is a critical decision that impacts not only immediate operational efficiency but also long-term safety and cost-effectiveness. By prioritizing manufacturers who demonstrate a steadfast commitment to advanced engineering, stringent quality control, comprehensive testing, and responsive customer support, businesses can secure a competitive edge. Products like the Hand Pallet Truck - CBY, built with a focus on durability, ergonomic design, and technical precision, exemplify the benchmarks set by industry leaders.

Investing in a high-quality hydraulic hand pallet truck from a reputable source ensures not only optimal performance but also compliance with international safety standards and a significant return on investment through reduced downtime and enhanced productivity. Our dedication to innovation and client satisfaction positions us as a premier choice among hand pallet jack manufacturers, ready to support your most challenging material handling requirements with customized solutions and unparalleled service.