Understanding Lifting Pallet Jacks Enhancing Efficiency in Material Handling

In today's fast-paced industrial landscape, efficiency and productivity are paramount. Businesses are continually seeking methods to streamline operations, especially in logistics and warehousing. One of the essential tools that contribute significantly to increased efficiency is the lifting pallet jack. This article delves into what lifting pallet jacks are, their types, advantages, and best practices for their effective use.

What is a Lifting Pallet Jack?

A lifting pallet jack is a manual or powered device designed to lift and move pallets containing goods in warehouses, distribution centers, and retail environments. Unlike traditional forklifts, pallet jacks are generally smaller, more maneuverable, and ideal for operating in tight spaces. They consist of two forks to slide beneath the pallet, a hydraulic lifting mechanism, and a handle that allows the operator to steer and control the jack.

Types of Lifting Pallet Jacks

Lifting pallet jacks can be categorized primarily into two types manual and powered

.1. Manual Pallet Jacks These are the most common type of pallet jacks and rely on hydraulic power generated by the operator's pumping action on the handle to lift the load. Manual pallet jacks are cost-effective and widely used in smaller operations where electrical outlets are not readily accessible. They can typically lift weights ranging from 4,500 to 5,500 pounds.

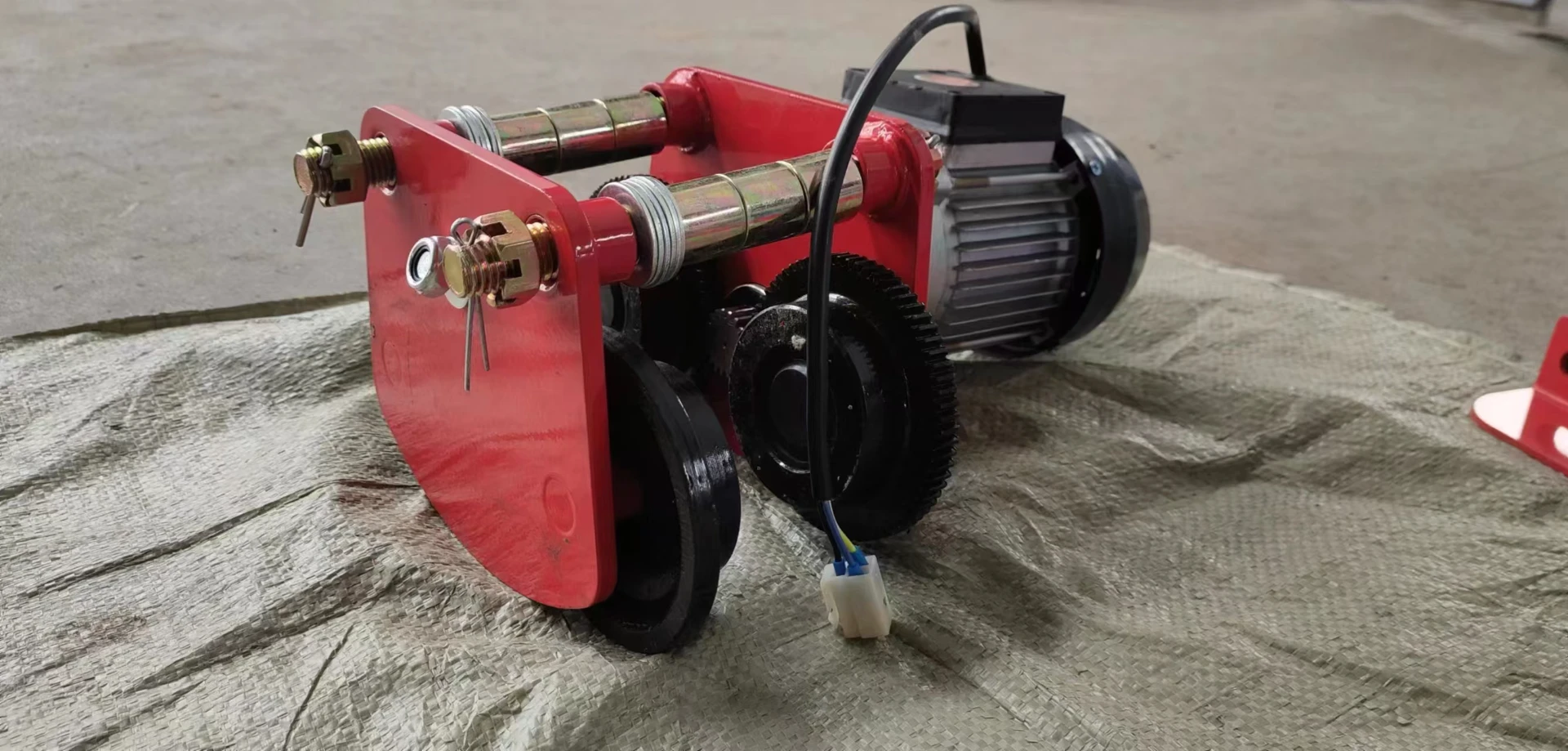

2. Powered Pallet Jacks Also known as electric pallet jacks or electric hand trucks, these devices have a battery-powered motor that lifts and moves pallets. Powered pallet jacks are suitable for heavy lifting and transporting operations, as they reduce the manual effort required by an operator. They also improve efficiency in larger warehouses by allowing quicker maneuvering and less fatigue for workers.

Advantages of Using Lifting Pallet Jacks

1. Efficiency and Speed Lifting pallet jacks can significantly cut down on the time it takes to move goods within a facility. Their design enables quick lifting and transporting, allowing for a fast-paced workflow.

2. Cost-Effectiveness Compared to larger machinery like forklifts, pallet jacks are less expensive to purchase and maintain. For businesses that require a practical solution for moving goods without the expense of heavy machinery, pallet jacks serve as an economical alternative.

3. Ease of Use Manual pallet jacks are user-friendly and require minimal training for new employees. This simplicity makes it easy for staff to adapt quickly to the equipment, increasing overall productivity.

4. Space Efficiency Their compact size allows them to operate in confined spaces where larger vehicles may struggle. This is particularly beneficial in crowded warehouses with narrow aisles.

5. Safety With the right operational training, using lifting pallet jacks can reduce the risk of injuries associated with manual lifting. Furthermore, advancements in design have emphasized safety features, making modern pallet jacks more secure for operators.

Best Practices for Using Lifting Pallet Jacks

1. Regular Maintenance Routine inspections and maintenance are essential to ensure that pallet jacks function safely and efficiently. Check hydraulic systems, wheels, and moving parts regularly.

2. Proper Training Even though pallet jacks are easier to use than forklifts, training still plays a critical role in ensuring safety and efficiency. Workers should be instructed on proper lifting techniques and how to maneuver the jack effectively.

3. Load Capacity Awareness Always be aware of the weight limits of the pallet jack being used. Overloading can lead to mechanical failure and pose safety risks.

4. Clear Pathways Ensure that the work area is free from obstructions. Clear pathways help prevent accidents and allow for swift movement of materials.

5. Secure Loads Ensure that loads are well-secured on the pallet. This prevents items from falling during transport, which could not only damage products but also pose a safety hazard.

Conclusion

Lifting pallet jacks are indispensable tools in material handling, offering businesses a versatile, efficient, and safe way to transport goods. Understanding their types, advantages, and best practices can help organizations maximize their operational efficiency while ensuring the well-being of their employees. As industries continue to evolve, the relevance of pallet jacks in maintaining smooth logistics operations remains steadfast. Through strategic implementation, companies can significantly enhance their productivity and work environment.