Mini electric hoists with a capacity of 200 kg are transforming the way industries handle lifting tasks by bringing efficiency and safety to various operations. These compact but powerful machines are integral in settings ranging from small workshops to large construction sites. Drawing from numerous real-world applications, this article delves into the practical benefits, technical specifications, and essential considerations surrounding the use of mini electric hoists, ensuring that your investment in such equipment is both informed and advantageous.

Compact and Robust The Design Advantage

The mini electric hoist’s design boasts a perfect blend of compactness and robustness, making it ideal for situations where space is a premium. With impressive power relative to its size, a 200 kg hoist can efficiently lift heavy loads without the need for bulky traditional systems. Industries have increasingly adopted these hoists due to their ease of installation and operation, which requires minimal space while maximizing lifting capabilities. The design allows for flexible mounting options, whether on scaffolds or building frameworks, providing versatile application potential.

Technical Specifications What to Expect

A typical mini electric hoist designed to lift up to 200 kg features a motor power of approximately 500W to 800W. It usually operates at a lifting speed of around 10 meters per minute, although variations exist depending on the brand and specific model. With a lifting height generally ranging up to 20 meters, these hoists come equipped with a galvanized steel wire rope to ensure durability and safety. Additionally, they include features like thermal protection to prevent overheating and ensure a longer operational lifespan.

Safety and Efficiency Key Attributes

Safety is paramount when operating any lifting equipment. The mini electric hoist is equipped with an emergency stop button and a limit switch to prevent the overrun of the hook, thus avoiding potential accidents. Its relatively slow and controlled ascent and descent speeds allow for precision handling of loads, minimizing risks to the operators and the goods. The remote-control feature further enhances safety by allowing operators to control the hoist from a safe distance, thereby reducing the likelihood of accidents resulting from proximity to the load.

Experience-Driven Insights Real-World Applications

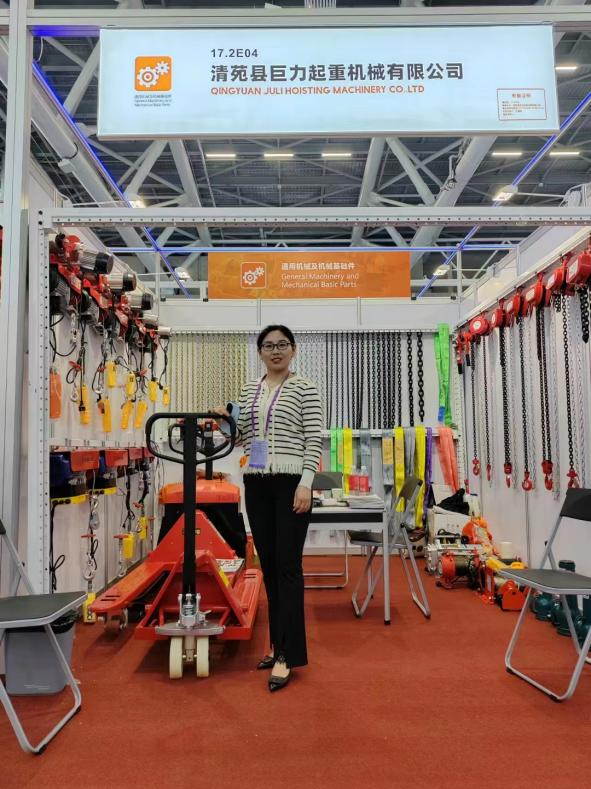

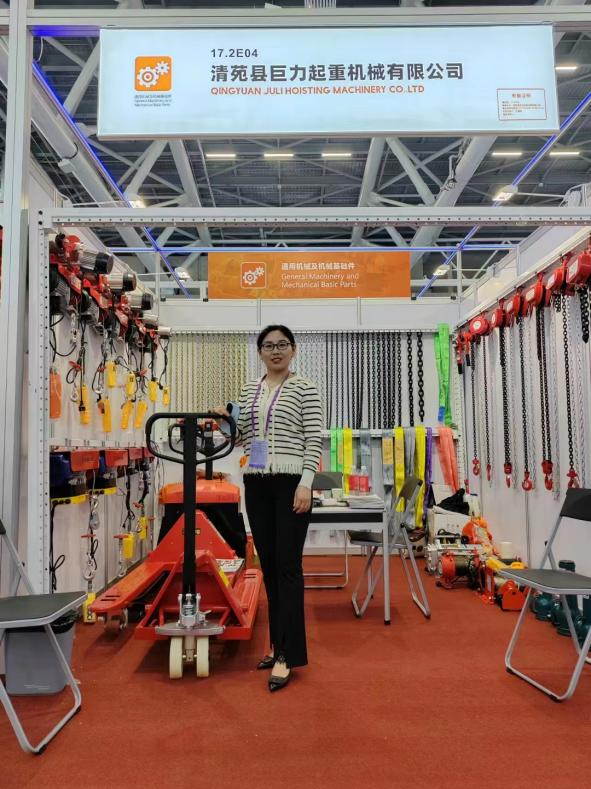

mini electric hoist 200 kg

Having consulted with industries utilizing mini electric hoists, their experiences underline the transformative impact of these machines. In construction, they are praised for their ability to efficiently lift materials to elevated work sites, drastically cutting down on manual labor and time. Workshops appreciate the reliability of a motorized solution to maneuver heavy components safely. Meanwhile, in manufacturing settings, these hoists have streamlined processes, allowing for quicker turnover rates and boosted productivity.

The Authority of Certification and Standards

When selecting a mini electric hoist, one should consider equipment compliant with international standards such as CE and ISO certifications. These certifications affirm the product's safety, quality, and performance, offering peace of mind to users responsible for maintaining operational safety standards. Engaging with suppliers who provide products verified by trusted third-party organizations consolidates trust in the product’s reliability.

Maintenance and Expertise Ensuring Longevity

Proper and regular maintenance is crucial for sustaining the function and safety of mini electric hoists. Users should receive comprehensive training about routine checks, such as inspecting wire ropes for fraying and ensuring that all controls are working correctly. Establishing a maintenance schedule based on manufacturer guidelines and workload intensity will help preserve the equipment's integrity and enhance its lifespan.

Trustworthiness through Innovation

Innovation in mini electric hoists is steadily evolving, with newer models introducing advanced features like wireless controls and smart integration. These advancements offer users better data insights, improved operational management, and enhanced safety mechanisms. By keeping abreast with these developments, industries can continue to leverage the full potential of their lifting equipment to maintain their competitive edge.

As industries embrace these versatile lifters, the 200 kg mini electric hoist stands out as an indispensable tool that combines reliability, efficiency, and safety in one compact equipment. Thus, understanding its advantages, features, and application can significantly enhance operational workflow, empowering businesses to achieve new productivity heights while safeguarding their workforce.