The Unseen Backbone: Understanding Hand Pallet Jacks in Modern Logistics

In the intricate ecosystem of global supply chains and material handling, the humble hand pallet jack plays a remarkably critical, yet often underestimated, role. These robust, manually operated machines are the workhorses of warehouses, retail outlets, and manufacturing floors worldwide, facilitating the efficient movement of palletized goods. Their simplicity, reliability, and cost-effectiveness make them indispensable for businesses of all sizes, from bustling distribution centers to local retail shops. The effectiveness of these tools, however, hinges significantly on the expertise and quality standards of their designers and fabricators. This comprehensive exploration delves into the world of hand pallet jack manufacturers, dissecting the intricate processes, technical specifications, and strategic advantages that define industry leaders like QYJULI, with a specific focus on their Hand Pallet Truck - CBY model. We aim to provide B2B decision-makers and technical personnel with a profound understanding of what distinguishes superior material handling equipment in today's demanding market.

The global market for material handling equipment, including hand pallet trucks, is projected to reach significant valuation, driven by the expansion of e-commerce, warehousing, and logistics infrastructure. According to a report by Grand View Research, the global material handling equipment market size was valued at USD 192.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 8.8% from 2023 to 2030. Within this vast market, hand pallet jacks represent a foundational segment, crucial for last-mile logistics and internal facility operations where larger, powered equipment might be impractical or uneconomical. The demand for durable, efficient, and ergonomically designed hand pallet truck solutions continues to climb, placing a heightened emphasis on the manufacturing prowess and innovation of leading hand pallet jack manufacturers.

Our discussion will cover the detailed manufacturing processes, crucial technical parameters, diverse application scenarios, and the paramount importance of selecting manufacturers adhering to the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness (). By presenting real-world data, product specifications, and insights into quality assurance, we aim to equip you with the knowledge necessary to make informed procurement decisions that optimize your operational efficiency and enhance safety.

The Core: Unveiling the Manufacturing Mastery of Hand Pallet Jacks

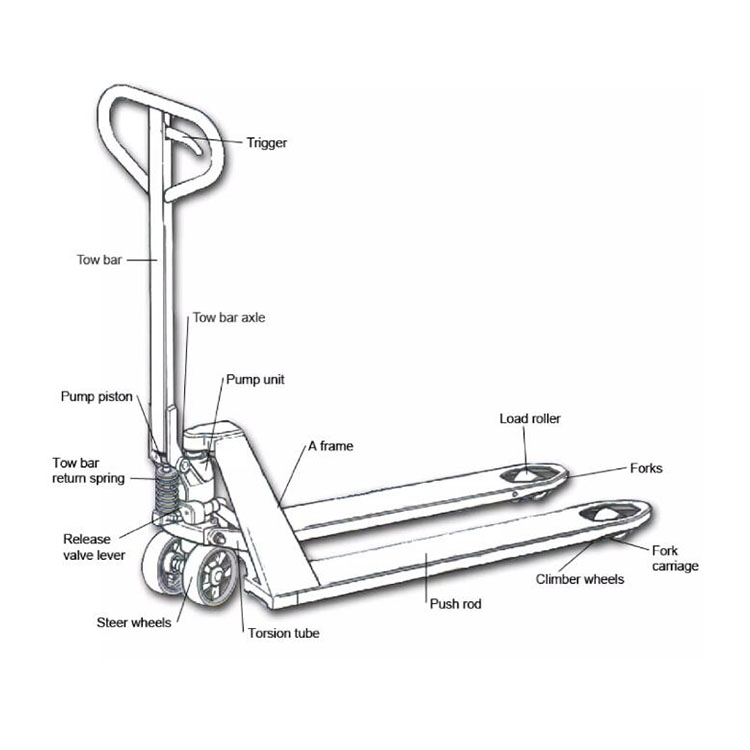

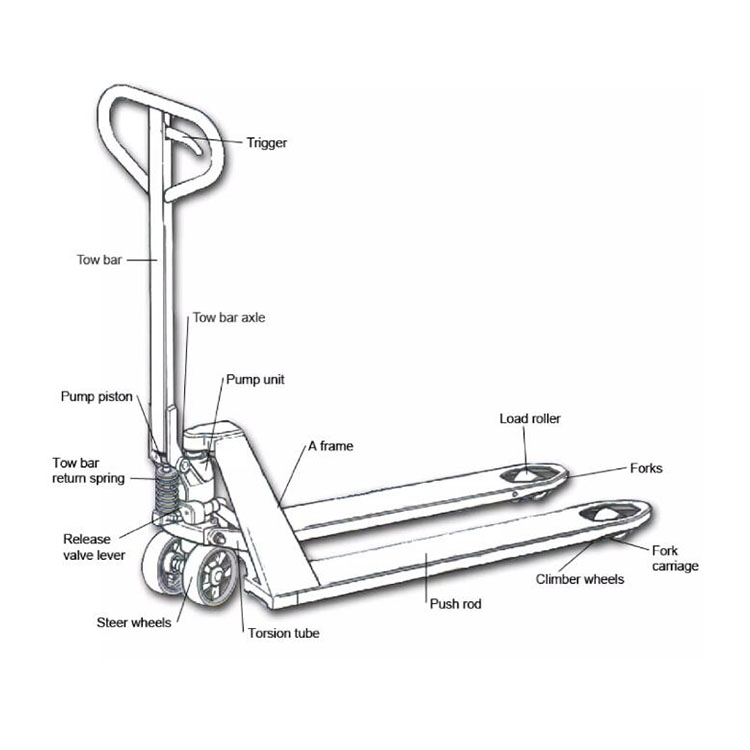

The creation of a high-performance hand pallet truck is a testament to precision engineering, material science, and rigorous quality control. Leading hand pallet jack manufacturers employ sophisticated processes to ensure each unit meets demanding performance and durability standards. The Hand Pallet Truck - CBY from QYJULI exemplifies this commitment, built with attention to every detail from initial design to final assembly.

Materials Engineering: The Foundation of Durability

- High-Grade Steel Alloys: The chassis and forks are typically constructed from heavy-gauge, high-tensile steel, often Q235 or equivalent structural steel, providing exceptional rigidity and load-bearing capacity. For specific applications requiring enhanced corrosion resistance, stainless steel variants (e.g., SUS304) or galvanized finishes may be utilized.

- Precision Castings and Forgings: Critical components, such as the hydraulic pump housing and steering mechanism, are often produced through advanced casting or forging processes. Casting ensures complex geometries with high material density, while forging provides superior strength and grain structure, minimizing stress points and increasing overall component lifespan.

- Wheel Materials: Wheels are a key interface with the floor and significantly impact maneuverability and wear. Common options include Nylon for hard-wearing, low-rolling resistance on smooth surfaces; Polyurethane (PU) for quieter operation, floor protection, and better traction; and Rubber for superior shock absorption and grip on uneven surfaces. The Hand Pallet Truck - CBY typically offers options for both Nylon and PU wheels, catering to diverse operational environments.

- Sealing Components: In the hydraulic hand pallet truck, high-quality seals (e.g., German-made oil seals) are paramount to prevent hydraulic fluid leakage, ensuring consistent lifting performance and extending pump life. These seals are designed to withstand high pressure and continuous operation, preventing common failures associated with inferior components.

Manufacturing Processes: A Symphony of Precision

The journey from raw material to a finished hydraulic hand pallet truck involves a series of meticulously controlled stages, often leveraging automated technologies for consistency and efficiency.

- Design and Engineering (CAD/CAE): The process begins with sophisticated Computer-Aided Design (CAD) software to create precise 3D models and blueprints. Computer-Aided Engineering (CAE), including Finite Element Analysis (FEA), is employed to simulate stress distribution under various loads, optimizing the structural integrity of the frame, forks, and hydraulic system. This digital prototyping minimizes physical prototypes and accelerates development, ensuring robust designs for all hand pallet jack manufacturers.

- Component Fabrication:

- Laser Cutting and Stamping: Steel sheets for forks and chassis components are cut with high precision using CNC laser cutters, ensuring exact dimensions and clean edges. Stamping presses form the structural elements, achieving consistent shapes and strengthening the material through cold working.

- CNC Machining: Critical parts, especially those in the hydraulic pump assembly, undergo Computer Numerical Control (CNC) machining. This highly precise method allows for the creation of components with extremely tight tolerances, crucial for the smooth and efficient operation of the hydraulic hand pallet truck pump unit.

- Welding: Robotic welding is extensively used for joining chassis and fork components. This automation ensures uniform, strong welds, free from human error, which are vital for the structural integrity and long-term durability of the pallet jack under heavy loads.

- Surface Treatment and Finishing: After welding, components undergo surface preparation, often including sandblasting to remove impurities and create an optimal surface for coating. Electrostatic powder coating is then applied, providing a durable, corrosion-resistant finish that protects the steel from environmental elements and enhances the aesthetic appeal. This process is more environmentally friendly than traditional liquid painting and offers superior chip resistance.

- Hydraulic System Assembly: This is the heart of the hydraulic hand pallet truck. Precision-machined pump components, cylinders, and valves are meticulously assembled in clean environments. Each pump unit is tested for pressure retention, smooth operation, and absence of leaks, ensuring consistent lifting and lowering performance.

- Final Assembly and Calibration: All major components – the chassis, forks, hydraulic unit, wheels, and steering handle – are assembled. Following assembly, each hand pallet jack undergoes calibration to ensure the hydraulic system operates at optimal efficiency, and all mechanical linkages function smoothly.

Rigorous Inspection and Quality Standards

Adherence to international standards is a hallmark of reputable hand pallet jack manufacturers. QYJULI's Hand Pallet Truck - CBY production follows stringent quality protocols:

- ISO 9001 Certification: This widely recognized quality management system standard ensures that manufacturers consistently provide products and services that meet customer and regulatory requirements. It dictates a systematic approach to processes, from design to delivery.

- ANSI B56.1 (Safety Standard for Low Lift and High Lift Trucks): While primarily for powered industrial trucks, many principles related to structural integrity, stability, and operational safety are adopted by leading hand pallet jack manufacturers to ensure the safety of manual equipment.

- CE Marking: For products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards. This is a critical assurance for international buyers.

- Individual Load Testing: Every completed hand pallet truck undergoes a rigorous load test, typically at 125% of its rated capacity, to verify its structural integrity and hydraulic system performance under stress.

- Fatigue Testing: Randomly selected units are subjected to prolonged, cyclical load operations to simulate years of use, identifying potential weak points and ensuring long-term durability and a design lifespan of 5-7 years under typical operational conditions.

By adhering to these stringent standards, QYJULI, as one of the prominent hand pallet jack manufacturers, ensures that their Hand Pallet Truck - CBY delivers consistent performance, exceptional durability, and a low total cost of ownership over its extended service life.

Key Technical Parameters and Performance Metrics: A Deep Dive

Understanding the technical specifications of a hand pallet truck is crucial for selecting the right equipment for specific operational needs. These parameters dictate the machine's capabilities, limitations, and suitability for various applications. For the Hand Pallet Truck - CBY, QYJULI focuses on optimizing these factors for versatility and performance.

Critical Specifications Explained

- Rated Capacity (Load Capacity): This is the maximum weight the hand pallet truck is designed to lift and transport safely. Standard capacities typically range from 2000 kg (4400 lbs) to 3000 kg (6600 lbs). The CBY model usually comes in 2500 kg or 3000 kg variants, making it suitable for a wide array of industrial applications. Exceeding this capacity can lead to structural damage, hydraulic failure, and safety hazards.

- Fork Length: This dimension (e.g., 1150 mm for standard Euro pallets, 1220 mm for North American pallets) determines the size of pallets the truck can effectively handle. Choosing the correct fork length ensures full support of the pallet, preventing load imbalance and potential tipping.

- Fork Width (Overall Width Over Forks): This measurement (e.g., 550 mm or 685 mm) influences the truck's maneuverability in confined spaces and its compatibility with different pallet types (e.g., standard Euro pallets often require 550mm, while wider pallets or open-bottom skids might need 685mm).

- Minimum Fork Height (Lowered Height): This is the height of the forks when fully lowered (e.g., 85 mm or 75 mm). It's crucial for compatibility with pallets that have minimal ground clearance.

- Maximum Lifting Height: The maximum elevation the forks can achieve (typically around 200 mm, or 7.9 inches). This height is sufficient to lift pallets off the ground for transport but not for stacking.

- Steering Wheel and Fork Wheel Diameter: Wheel dimensions and materials (Nylon, PU) significantly affect ease of rolling, floor protection, and maneuverability. Larger wheels generally offer easier movement over obstacles, while dual fork wheels distribute weight better and reduce floor markings.

- Turning Radius: This specification indicates how tightly the hand pallet truck can turn, influencing its suitability for narrow aisles and congested areas. A smaller turning radius allows for greater maneuverability.

- Weight of the Unit: The net weight of the pallet truck itself (e.g., 65-80 kg for a standard model) impacts ease of handling when empty and shipping costs.

Hand Pallet Truck - CBY: Typical Specifications Overview

| Parameter |

CBY Model Range (Typical) |

Importance/Note |

| Rated Capacity |

2500 kg - 3000 kg (5500 - 6600 lbs) |

Determines max load; matched to common industrial pallet weights. |

| Fork Length (L) |

1150 mm (45.3 in) or 1220 mm (48 in) |

Compatibility with Euro, standard US pallets. |

| Fork Width (W, overall) |

550 mm (21.7 in) or 685 mm (27 in) |

Influences maneuverability and pallet entry. |

| Min. Fork Height (H1) |

85 mm (3.3 in) or 75 mm (3.0 in) |

Essential for low-profile pallets. |

| Max. Lifting Height (H2) |

200 mm (7.9 in) |

Standard lift for ground clearance. |

| Steering Wheel Material |

Polyurethane (PU) or Nylon |

PU for quietness, floor protection; Nylon for hard-wearing. |

| Fork Wheel Material |

Polyurethane (PU) or Nylon (Tandem configuration) |

Tandem wheels improve stability and reduce rolling resistance. |

| Net Weight |

~65-80 kg (143-176 lbs) |

Ease of manual handling and transport. |

| Pump Type |

Integrated (Compact) or Welded (Robust) |

Integrated offers compact design, welded offers higher strength. |

These specifications are not merely numbers; they represent the engineering integrity and functional capabilities that hand pallet jack manufacturers build into their products. A well-specified hand pallet truck, like the CBY, ensures efficient operation, minimal wear on both the equipment and the floor, and enhanced safety for operators.

Diverse Application Scenarios and Industry-Specific Advantages

The versatility of the hand pallet truck makes it an indispensable tool across a broad spectrum of industries. While its primary function remains consistent – moving palletized goods – the specific demands of each sector necessitate unique features and advantages offered by experienced hand pallet jack manufacturers.

General Applications: Ubiquitous Utility

- Warehousing & Logistics: Fundamental for loading/unloading trucks, reorganizing inventory, and moving goods within receiving/shipping areas. Their compact size allows navigation in tight aisles where forklifts cannot operate.

- Retail & Supermarkets: Ideal for stocking shelves from backroom storage, moving seasonal displays, and handling daily deliveries with minimal disruption to customer flow.

- Manufacturing Facilities: Used for transporting raw materials to production lines, moving work-in-progress between stations, and staging finished goods for shipment. Their manual nature ensures precise positioning, crucial in assembly areas.

- Cold Storage & Food Processing: Specialized models with rust-resistant components and low-temperature hydraulic oil are essential in refrigerated environments, preventing corrosion and ensuring smooth operation.

Specialized Industry Applications & Advantages

Leading hand pallet jack manufacturers like QYJULI understand that one size does not fit all. They offer specialized versions of their hydraulic hand pallet truck to meet the rigorous demands of niche industries:

- Petrochemical & Hazardous Environments: In these settings, spark-proof and anti-corrosion features are paramount. Specialized hand pallet truck models may feature non-sparking forks (e.g., stainless steel, bronze-coated), explosion-proof hydraulic systems, and anti-static wheels. Advantages include enhanced safety in volatile atmospheres, adherence to ATEX directives, and long-term resistance to aggressive chemicals, contributing to a safer and more compliant operational environment.

- Metallurgy & Heavy Industry: This sector requires equipment capable of handling extremely heavy and often hot loads. Robust, heavy-duty hand pallet truck models with reinforced frames, superior bearing systems, and high-temperature resistant components are necessary. The advantages lie in their ability to withstand brutal conditions, reliably move molten metal or heavy castings, and minimize downtime in high-stress operations.

- Water Treatment & Chemical Plants: Exposure to corrosive chemicals and high humidity mandates the use of stainless steel or specially coated hand pallet truck models. These units excel in preventing rust and material degradation, ensuring a significantly longer lifespan compared to standard models, thereby reducing replacement costs and maintaining operational integrity in challenging, humid, or chemically active environments.

- Pharmaceutical & Food Processing: Hygiene is critical. Stainless steel hand pallet jacks with smooth, easy-to-clean surfaces and often FDA-approved lubricants are used to prevent contamination. Advantages include compliance with strict sanitary regulations, ease of sterilization, and prevention of bacterial growth, which are crucial for product safety and quality.

Operational Advantages of Hand Pallet Trucks

- Cost-Effectiveness: Lower initial purchase price compared to forklifts or electric pallet trucks, minimal maintenance requirements, and zero fuel/electricity costs lead to significant long-term savings.

- Energy Efficiency: As manually operated devices, they consume no energy, making them an environmentally friendly choice and ideal for "green" initiatives.

- Maneuverability: Their compact design and human-powered operation allow for precise control and navigation in extremely tight spaces, narrow aisles, and inside trucks or container111s, where larger equipment cannot operate.

- Low Maintenance: With fewer complex components, the maintenance schedule is simple, primarily focusing on lubrication and occasional seal replacement. This translates to higher uptime and lower operational expenditure.

- Enhanced Safety: Simpler operation reduces the risk of complex machinery-related accidents. Properly trained operators can move loads safely and efficiently, especially in pedestrian-heavy areas.

The Hand Pallet Truck - CBY, through its robust design and optional specialized features, offers these advantages, ensuring it's not just a tool, but a strategic asset for businesses seeking efficient and safe material handling solutions. QYJULI's dedication to meeting diverse industry needs underscores their position as a leading choice among hand pallet jack manufacturers.

Strategic Advantages: Why Choose Leading Hand Pallet Jack Manufacturers?

When investing in material handling equipment, the choice of manufacturer goes beyond mere product specifications. It's about securing reliability, innovation, and long-term support. Leading hand pallet jack manufacturers distinguish themselves through several strategic advantages that translate directly into operational benefits for their clients.

Innovation and Research & Development (R&D)

The best hand pallet jack manufacturers are not content with traditional designs. They continually invest in R&D to enhance ergonomics, improve hydraulic efficiency, and explore new materials. For instance, QYJULI focuses on incorporating ergonomic handles, reinforced fork tips for easier pallet entry, and improved pump designs that require less effort per stroke, directly translating to reduced operator fatigue and increased productivity. This commitment to innovation is critical in developing next-generation hydraulic hand pallet truck models that push the boundaries of manual material handling.

Customization Capabilities

While standard models serve a broad market, many businesses have unique requirements. Top hand pallet jack manufacturers offer extensive customization options, including:

- Special Fork Dimensions: For non-standard pallets or unique load configurations.

- Load Capacity Enhancements: For extremely heavy applications beyond standard capacities.

- Specialized Coatings: Such as galvanization or marine-grade epoxy coatings for harsh, corrosive environments (e.g., coastal facilities, chemical storage).

- Integrated Scales: For weighing goods as they are moved, enhancing efficiency in shipping and inventory management.

- Brake Systems: For use on inclines or in situations requiring additional load control.

This flexibility ensures that clients receive a hand pallet truck perfectly tailored to their operational nuances, maximizing utility and return on investment.

Comprehensive After-Sales Support and Parts Availability

A robust after-sales network is a crucial indicator of a manufacturer's commitment to its customers. Reputable hand pallet jack manufacturers provide:

- Ready Availability of Spare Parts: Ensuring quick repairs and minimal downtime. This includes common wear parts like wheels, seals, and pump components.

- Technical Support: Access to expert advice for troubleshooting and maintenance.

- Warranty Programs: Clear and reliable warranty terms that cover manufacturing defects, providing peace of mind.

QYJULI stands out in this regard, offering extensive support for their Hand Pallet Truck - CBY, minimizing operational interruptions for their global clientele.

Certifications and Compliance

Beyond mandatory regulatory compliance (like CE marking for Europe), leading hand pallet jack manufacturers often pursue additional certifications and adhere to voluntary standards. These may include GS (Geprüfte Sicherheit - "Tested Safety") mark from Germany, indicating compliance with German product safety law, or specific industry certifications relevant to sectors like food or pharmaceuticals (e.g., stainless steel models for FDA compliance). These certifications serve as independent verification of product quality, safety, and performance.

Environmental Responsibility

Increasingly, businesses prioritize suppliers with strong environmental ethics. Top hand pallet jack manufacturers integrate sustainable practices into their operations, from using recycled materials where appropriate, implementing energy-efficient manufacturing processes, to adopting environmentally friendly coatings (like powder coating) and managing waste responsibly. Choosing such manufacturers aligns with corporate sustainability goals and enhances brand reputation.

The cumulative effect of these strategic advantages is a product that offers not just immediate utility but long-term value, reliability, and support. For a B2B buyer, this translates into reduced operational costs, enhanced safety, and greater peace of mind, making the choice of a reputable hand pallet jack manufacturer a critical business decision.

Ensuring Trust and Reliability: The Framework in Practice

In today’s competitive B2B landscape, the decision to partner with a hand pallet jack manufacturer extends beyond price and product features. Buyers increasingly scrutinize a manufacturer's Expertise, Experience, Authoritativeness, and Trustworthiness (). QYJULI exemplifies these principles in its approach to manufacturing and customer relations for products like the Hand Pallet Truck - CBY.

Expertise: Deep Industry Knowledge and Technical Proficiency

Expertise is demonstrated through a profound understanding of material handling challenges and the engineering solutions required to overcome them. For hand pallet jack manufacturers, this means:

- Material Science Application: Knowledge of how different steel alloys, polymers, and hydraulic fluids behave under stress, temperature variations, and corrosive environments to select optimal materials for longevity and performance. For example, understanding the benefits of chroming hydraulic pistons for corrosion resistance or using specific high-pressure seals to prevent leaks in the hydraulic hand pallet truck.

- Hydraulic System Mastery: Expertise in designing and manufacturing efficient, leak-proof hydraulic pumps and cylinders that provide smooth lifting and controlled lowering, even under maximum load. This includes understanding cavitation, fluid dynamics, and wear mechanisms.

- Ergonomic Design Principles: Integrating ergonomic factors to reduce operator strain and improve productivity. This includes optimal handle height, easy-to-pump mechanisms, and smooth-rolling wheels.

- Manufacturing Process Optimization: Continuously refining production techniques (e.g., robotic welding, precision CNC machining, advanced powder coating) to achieve consistent quality, reduce defects, and improve efficiency.

Experience: Proven Track Record and Real-World Application

Experience is built over years of serving diverse clients and learning from real-world applications. QYJULI has proudly served the material handling sector for over two decades, accumulating invaluable experience. This translates to:

- Problem-Solving Capabilities: The ability to foresee common operational challenges (e.g., wheel wear on abrasive floors, hydraulic pump failures due to inadequate sealing) and design solutions into the product from the outset.

- Client Feedback Integration: Using insights from thousands of clients across various industries to iteratively improve product design and functionality. For instance, feedback on handle comfort leading to ergonomic redesigns.

- Service Case Resolution: A history of successfully resolving service issues, demonstrating a commitment to customer satisfaction and product longevity. This often involves developing comprehensive diagnostics and repair protocols.

- Long-Term Performance: Products like the Hand Pallet Truck - CBY benefit from years of field data, proving their durability and reliability under various conditions, from sub-zero temperatures in cold storage to continuous use in busy warehouses.

Authoritativeness: Industry Recognition and Credibility

Authoritativeness is established through official recognitions and consistent adherence to high standards. For hand pallet jack manufacturers, this means:

- ISO 9001 Quality Management Certification: As mentioned, this is a fundamental pillar of authority, proving a systematic approach to quality.

- CE & GS Markings: Demonstrating compliance with rigorous European safety and quality standards.

- Strategic Partnerships: Collaborations with major logistics companies, equipment rental firms, or large industrial enterprises that endorse the manufacturer's products.

- Industry Awards and Recognitions: Accolades for innovation, design, or manufacturing excellence.

- Published Test Data and Reports: Providing transparent performance data from independent testing labs or internal quality assurance, confirming rated capacities, lift cycles, and durability.

Trustworthiness: Transparency and Customer-Centric Policies

Trustworthiness is built on clear communication, reliable services, and strong commitments. QYJULI ensures trustworthiness through:

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of a Hand Pallet Truck - CBY?

A1: Under normal operational conditions and with regular maintenance, a QYJULI Hand Pallet Truck - CBY is designed for a service life of 5-7 years, often exceeding this with proper care. Our robust construction and high-quality components ensure long-term durability.

Q2: Are spare parts readily available for the CBY model?

A2: Yes, QYJULI maintains a comprehensive inventory of genuine spare parts for all our models, including the CBY. This ensures minimal downtime for any necessary repairs or replacements. Our global distribution network facilitates efficient delivery.

Q3: Can the Hand Pallet Truck - CBY be customized for specific needs?

A3: Absolutely. As leading hand pallet jack manufacturers, we offer customization options for fork dimensions, specialized wheel materials, various coatings (e.g., galvanized, stainless steel), and integrated weighing scales to meet unique industry requirements.

Q4: What maintenance is required for a hydraulic hand pallet truck?

A4: Maintenance is straightforward. Key steps include regular lubrication of moving parts (wheels, bearings), checking hydraulic fluid levels, inspecting for leaks, and ensuring the pump handle mechanism operates smoothly. A detailed maintenance guide is provided with each unit.

Delivery Schedule and Logistics

Clear and predictable delivery timelines are crucial. QYJULI leverages an efficient supply chain and logistics network to ensure timely dispatch and delivery. Standard models are typically shipped within 7-14 business days, while customized orders may take 3-4 weeks, depending on complexity. Transparent communication regarding lead times and tracking information fosters confidence.

Warranty and Quality Assurance

QYJULI stands behind the quality of its products with a comprehensive warranty. For the Hand Pallet Truck - CBY, a standard 1-year warranty on major components (frame, pump) and 6-month warranty on wear parts (wheels, seals) is typically provided, covering manufacturing defects. This commitment is supported by stringent quality control at every stage of production, including individual unit testing and batch quality checks.

Dedicated Customer Support

Accessible and responsive customer support is paramount for trustworthiness. QYJULI provides multi-channel support (phone, email, online portal) to assist with product inquiries, technical support, and after-sales service. This includes a team of trained professionals who can offer guidance on product selection, maintenance, and troubleshooting, ensuring that clients receive prompt and effective assistance throughout the lifespan of their hand pallet truck.

Conclusion: Partnering for Material Handling Excellence

The selection of a hand pallet truck is a strategic decision that impacts operational efficiency, safety, and long-term costs within any material handling environment. As this comprehensive guide illustrates, understanding the intricate manufacturing processes, key technical parameters, diverse application scenarios, and the strategic advantages offered by leading hand pallet jack manufacturers is vital for informed procurement.

QYJULI, through its Hand Pallet Truck - CBY model, exemplifies the commitment to engineering excellence, robust construction, and customer-centric policies that define a top-tier manufacturer. By adhering to stringent quality standards, offering versatile solutions, and providing unwavering support, QYJULI ensures that businesses can rely on their equipment to meet the most demanding operational challenges. The emphasis on principles – Expertise, Experience, Authoritativeness, and Trustworthiness – solidifies the partnership between manufacturer and client, guaranteeing not just a product, but a comprehensive solution for efficient and safe material handling.

As industries continue to evolve with growing demands for faster throughput and optimized logistics, the role of a reliable hand pallet truck remains paramount. Choosing a manufacturer that invests in innovation, quality, and customer satisfaction is not merely a purchase; it's an investment in the seamless flow of your operations and the long-term success of your business. The future of material handling will undoubtedly see further advancements, but the foundational reliability provided by expert hand pallet jack manufacturers will remain a constant in supporting global commerce.

References

- Grand View Research. (2023). Material Handling Equipment Market Size, Share & Trends Analysis Report By Product, By System, By Application, By Function, By Industry Vertical, By Region, And Segment Forecasts, 2023 - 2030.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements.

- American National Standards Institute. (2017). ANSI/ITSDF B56.1-2017 - Safety Standard for Low Lift and High Lift Trucks.

- European Parliament and Council. (2006). Directive 2006/42/EC on machinery. (Known as the Machinery Directive, related to CE Marking).

- National Institute for Occupational Safety and Health (NIOSH). (2016). Ergonomics and Musculoskeletal Disorders. (Provides general principles for ergonomic design in manual handling equipment).