In the dynamic landscape of modern logistics and warehousing, efficient material handling equipment is not just a convenience, but a necessity for operational excellence. Among the most fundamental yet indispensable tools is the hand pallet truck, commonly known as a hand pallet jack. These versatile devices are the backbone of many supply chains, enabling the swift and safe movement of goods across various industrial and commercial settings. Understanding the capabilities and quality standards set by leading hand pallet jack manufacturers is paramount for businesses seeking to optimize their workflow and reduce manual labor.

The continuous innovation by these manufacturers ensures that businesses have access to durable, ergonomic, and highly efficient equipment that meets diverse operational demands. From the bustling floors of distribution centers to the precise movements required in retail environments, a reliable hand pallet truck significantly enhances productivity and safety. This article delves into the critical aspects of selecting a top-tier hand pallet jack, focusing on manufacturing excellence, technical specifications, application versatility, and the comprehensive support services provided by industry leaders.

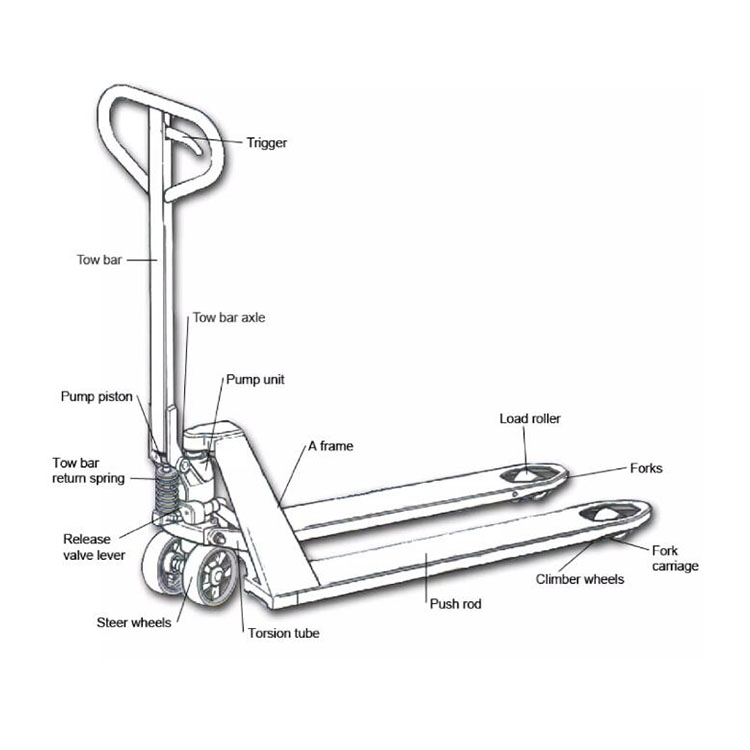

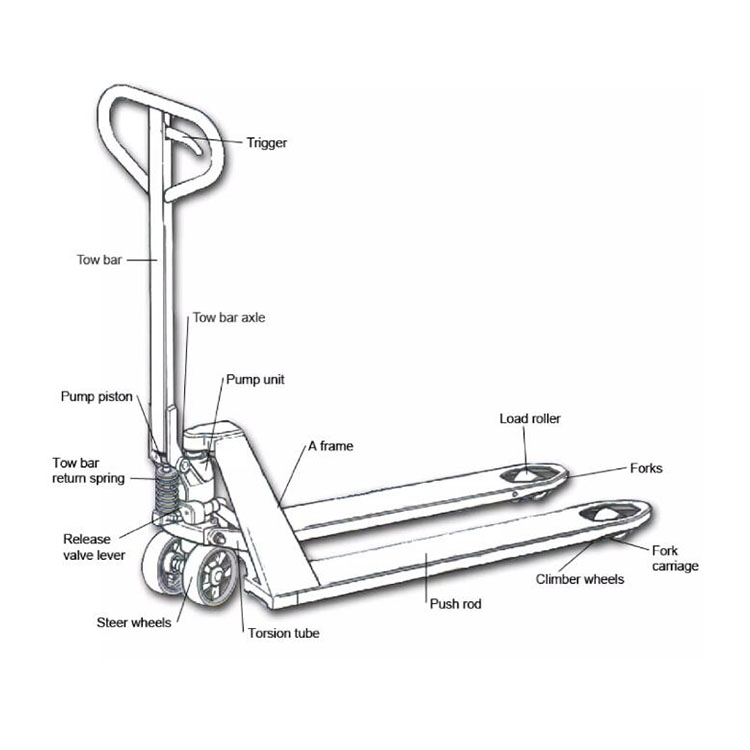

The creation of a high-quality hand pallet truck is a sophisticated process that combines robust material selection with advanced manufacturing techniques. Reputable hand pallet jack manufacturers adhere to stringent quality control protocols at every stage, ensuring the final product delivers superior performance and longevity. The journey begins with the selection of high-grade steel for the chassis and forks, often employing Q235B or equivalent structural steel known for its excellent strength and weldability. For critical components like the hydraulic pump body, precision casting or forging using high-tensile cast iron ensures optimal pressure resistance and leak prevention.

Manufacturing steps typically include:

The focus on anti-corrosion materials and robust design makes these hand pallet jacks ideal for demanding sectors like chemical processing, food & beverage, and pharmaceutical industries where cleanliness and material integrity are paramount. The design also often incorporates features for energy efficiency, though less pronounced than in electric models, through optimized pump mechanics ensuring less effort per lift.

When evaluating a hand pallet truck, understanding its technical specifications is essential for matching the equipment to specific operational needs. The Hand Pallet Truck - CBY, a prime example from reputable hand pallet jack manufacturers, showcases superior design and robust engineering tailored for heavy-duty applications. Its specifications demonstrate a commitment to both performance and user ergonomics. The integrated pump design, a hallmark of quality hydraulic hand pallet truck, ensures minimal maintenance and an extended lifespan due to fewer leakage points and enhanced structural integrity compared to welded pump types.

Below is a typical specification table for a high-performance hydraulic hand pallet truck like the CBY model, highlighting critical parameters that influence its suitability for various tasks:

| Parameter | Description | Value (CBY Model Example) |

|---|---|---|

| Rated Load Capacity | Maximum weight the truck can safely lift and transport. | 2500 kg (5500 lbs) / 3000 kg (6600 lbs) |

| Fork Length | Length of the forks, matching common pallet sizes. | 1150 mm / 1220 mm |

| Fork Width (Overall) | Total width across both forks. | 550 mm / 685 mm |

| Min. Fork Height | Lowest height of forks when fully lowered. | 85 mm (3.3 inches) |

| Max. Lift Height | Maximum height the forks can be lifted. | 200 mm (7.9 inches) |

| Steering Wheel Diameter | Diameter of the front steering wheels. | Ø180 mm |

| Fork Wheel Diameter | Diameter of the load wheels under the forks. | Ø80 mm |

| Wheel Material Options | Material for wheels, influencing noise, floor protection, and durability. | Nylon, PU (Polyurethane), Rubber |

| Pump Type | Integrated (cast) or Welded hydraulic pump. Integrated offers superior durability. | Integrated (Cast) |

The CBY model, with its robust integrated pump and high-strength steel construction, exemplify the quality and reliability that businesses expect from leading hand pallet jack manufacturers. Its adaptability across various wheel materials further allows customization for specific floor conditions, ranging from smooth concrete to uneven surfaces, optimizing both longevity and operational noise.

A well-designed hand pallet truck is a cornerstone of efficiency in an array of industrial sectors. Its manual operation provides unparalleled flexibility, making it an ideal choice for areas where electric or motorized equipment might be impractical due to space constraints, cost, or specific environmental requirements. These versatile machines find their utility in diverse environments, from compact retail backrooms to sprawling manufacturing facilities and critical logistics hubs.

The primary advantages of opting for a quality hydraulic hand pallet truck from reputable hand pallet jack manufacturers include cost-effectiveness, minimal maintenance, and ease of operation. Unlike their electric counterparts, they do not require battery charging infrastructure, significantly reducing operational overhead. Their robust construction ensures a long service life, even under continuous heavy use. Furthermore, modern designs often incorporate ergonomic handles and low-effort pumping systems, reducing operator fatigue and enhancing safety. This focus on user experience and durability solidifies their position as an indispensable asset in material handling operations.

Selecting the appropriate hand pallet jack manufacturers is a strategic decision that impacts long-term operational efficiency and safety. The market offers a range of options, but discerning buyers focus on several key differentiators beyond just price. A true industry leader is characterized by its commitment to quality, innovation, and customer support, reflecting its authority and trustworthiness in the field. Here's a comparative overview of what distinguishes top-tier manufacturers:

| Feature/Criteria | Leading Manufacturer | Average Manufacturer |

|---|---|---|

| Material Quality | High-grade structural steel (e.g., Q235B/345B), precision cast/forged components. | Standard steel, potentially welded or lower-quality cast components. |

| Hydraulic Pump | Integrated (one-piece) cast pump, leak-proof design, durable seals. | Welded pump, higher risk of leakage over time. |

| Testing & Certification | Rigorous 125% static/110% dynamic load testing, ISO 9001, CE. | Basic load tests, limited or no international certifications. |

| Ergonomics | Ergonomic handle, low-effort pump, quiet operation, diverse wheel options. | Basic handle, higher pumping effort, limited wheel choices. |

| Customization | Ability to customize fork dimensions, capacities, and special features. | Limited or no customization options. |

| After-Sales Support | Comprehensive warranty, readily available spare parts, responsive technical support. | Short warranty, difficulty sourcing parts, minimal support. |

A manufacturer's service history and global reach also speak volumes about their experience and authority. Companies with decades of experience serving clients in numerous countries often demonstrate a deeper understanding of diverse industry needs and regulatory requirements. This extensive experience translates directly into product reliability and customer satisfaction, essential factors for any business investment.

While standard models of hand pallet truck fulfill the majority of material handling needs, certain industries or unique operational environments demand tailored solutions. Leading hand pallet jack manufacturers recognize this and offer extensive customization options to meet precise client specifications. This capability is crucial for businesses dealing with non-standard pallet sizes, unique material compositions, or operating in specialized conditions such as corrosive environments, cleanrooms, or extremely narrow aisles.

Customization can range from:

This ability to provide bespoke solutions highlights a manufacturer's expertise and commitment to solving complex material handling challenges. It ensures that businesses don't have to compromise on efficiency or safety due to equipment limitations, leading to optimized workflows and improved return on investment. Collaborating with an experienced manufacturer for custom solutions leverages their technical know-how and design capabilities to create a truly fit-for-purpose tool.

Trustworthiness is a cornerstone when choosing hand pallet jack manufacturers. It’s built not just on product quality but also on the transparency of certifications, the robustness of warranty policies, and the efficiency of after-sales support. Reputable manufacturers will openly display their adherence to international quality and safety standards, providing tangible proof of their commitment to excellence.

Look for manufacturers who comply with or exceed standards such as:

These certifications provide a third-party validation of the manufacturer's processes and product safety, bolstering confidence in their offerings. Test data, such as load deflection tests or pump cycle tests (e.g., 20,000+ cycles for a robust hydraulic hand pallet truck), further substantiate claims of durability and performance.

Most manufacturers offer a standard delivery period, often between 2-4 weeks for standard models, with express options available. For custom orders, lead times may vary. A robust warranty, typically 12-24 months for major components (like the hydraulic pump) and 6 months for wear parts (like wheels), signals the manufacturer's confidence in their product's durability. Comprehensive customer support, including easy access to spare parts and technical assistance, ensures minimal downtime and a seamless ownership experience.

In a world increasingly driven by automation, the fundamental utility of a manual hand pallet truck remains undiminished. Its simplicity, reliability, and cost-effectiveness make it an indispensable asset for businesses of all sizes, from small enterprises to large-scale distribution networks. The dedication of leading hand pallet jack manufacturers to continuous improvement in design, material science, and manufacturing processes ensures that these tools continue to evolve, offering greater efficiency, enhanced safety, and extended operational lifespans. Investing in a high-quality hand pallet truck is not merely a purchase; it is an investment in operational resilience, workforce safety, and long-term productivity.

By prioritizing manufacturers who demonstrate expertise through rigorous testing, offer comprehensive support, and provide transparent product specifications, businesses can confidently equip their operations with the best material handling solutions available. The Hand Pallet Truck - CBY, as highlighted, serves as a testament to the quality and reliability that defines industry-leading products, ready to meet the demanding requirements of modern logistics.

In the dynamic landscape of modern logistics and warehousing, efficient material handling equipment is not just a convenience, but a necessity for operational excellence. Among the most fundamental yet indispensable tools is the hand pallet truck, commonly known as a hand pallet jack. These versatile devices are the backbone of many supply chains, enabling the swift and safe movement of goods across various industrial and commercial settings. Understanding the capabilities and quality standards set by leading hand pallet jack manufacturers is paramount for businesses seeking to optimize their workflow and reduce manual labor.

The continuous innovation by these manufacturers ensures that businesses have access to durable, ergonomic, and highly efficient equipment that meets diverse operational demands. From the bustling floors of distribution centers to the precise movements required in retail environments, a reliable hand pallet truck significantly enhances productivity and safety. This article delves into the critical aspects of selecting a top-tier hand pallet jack, focusing on manufacturing excellence, technical specifications, application versatility, and the comprehensive support services provided by industry leaders.

The creation of a high-quality hand pallet truck is a sophisticated process that combines robust material selection with advanced manufacturing techniques. Reputable hand pallet jack manufacturers adhere to stringent quality control protocols at every stage, ensuring the final product delivers superior performance and longevity. The journey begins with the selection of high-grade steel for the chassis and forks, often employing Q235B or equivalent structural steel known for its excellent strength and weldability. For critical components like the hydraulic pump body, precision casting or forging using high-tensile cast iron ensures optimal pressure resistance and leak prevention.

Manufacturing steps typically include:

The focus on anti-corrosion materials and robust design makes these hand pallet jacks ideal for demanding sectors like chemical processing, food & beverage, and pharmaceutical industries where cleanliness and material integrity are paramount. The design also often incorporates features for energy efficiency, through optimized pump mechanics ensuring less effort per lift, making them a sustainable choice for many operations.

When evaluating a hand pallet truck, understanding its technical specifications is essential for matching the equipment to specific operational needs. The Hand Pallet Truck - CBY, a prime example from reputable hand pallet jack manufacturers, showcases superior design and robust engineering tailored for heavy-duty applications. Its specifications demonstrate a commitment to both performance and user ergonomics. The integrated pump design, a hallmark of quality hydraulic hand pallet truck, ensures minimal maintenance and an extended lifespan due to fewer leakage points and enhanced structural integrity compared to welded pump types.

Below is a typical specification table for a high-performance hydraulic hand pallet truck like the CBY model, highlighting critical parameters that influence its suitability for various tasks:

| Parameter | Description | Value (CBY Model Example) |

|---|---|---|

| Rated Load Capacity | Maximum weight the truck can safely lift and transport. | 2500 kg (5500 lbs) / 3000 kg (6600 lbs) |

| Fork Length | Length of the forks, matching common pallet sizes. | 1150 mm / 1220 mm |

| Fork Width (Overall) | Total width across both forks. | 550 mm / 685 mm |

| Min. Fork Height | Lowest height of forks when fully lowered. | 85 mm (3.3 inches) |

| Max. Lift Height | Maximum height the forks can be lifted. | 200 mm (7.9 inches) |

| Steering Wheel Diameter | Diameter of the front steering wheels. | Ø180 mm |

| Fork Wheel Diameter | Diameter of the load wheels under the forks. | Ø80 mm |

| Wheel Material Options | Material for wheels, influencing noise, floor protection, and durability. | Nylon, PU (Polyurethane), Rubber |

| Pump Type | Integrated (cast) or Welded hydraulic pump. Integrated offers superior durability. | Integrated (Cast) |

The CBY model, with its robust integrated pump and high-strength steel construction, exemplify the quality and reliability that businesses expect from leading hand pallet jack manufacturers. Its adaptability across various wheel materials further allows customization for specific floor conditions, ranging from smooth concrete to uneven surfaces, optimizing both longevity and operational noise.

A well-designed hand pallet truck is a cornerstone of efficiency in an array of industrial sectors. Its manual operation provides unparalleled flexibility, making it an ideal choice for areas where electric or motorized equipment might be impractical due to space constraints, cost, or specific environmental requirements. These versatile machines find their utility in diverse environments, from compact retail backrooms to sprawling manufacturing facilities and critical logistics hubs.

The primary advantages of opting for a quality hydraulic hand pallet truck from reputable hand pallet jack manufacturers include cost-effectiveness, minimal maintenance, and ease of operation. Unlike their electric counterparts, they do not require battery charging infrastructure, significantly reducing operational overhead. Their robust construction ensures a long service life, even under continuous heavy use. Furthermore, modern designs often incorporate ergonomic handles and low-effort pumping systems, reducing operator fatigue and enhancing safety. This focus on user experience and durability solidifies their position as an indispensable asset in material handling operations.

Selecting the appropriate hand pallet jack manufacturers is a strategic decision that impacts long-term operational efficiency and safety. The market offers a range of options, but discerning buyers focus on several key differentiators beyond just price. A true industry leader is characterized by its commitment to quality, innovation, and customer support, reflecting its authority and trustworthiness in the field. Here's a comparative overview of what distinguishes top-tier manufacturers:

| Feature/Criteria | Leading Manufacturer | Average Manufacturer |

|---|---|---|

| Material Quality | High-grade structural steel (e.g., Q235B/345B), precision cast/forged components. | Standard steel, potentially welded or lower-quality cast components. |

| Hydraulic Pump | Integrated (one-piece) cast pump, leak-proof design, durable seals. | Welded pump, higher risk of leakage over time. |

| Testing & Certification | Rigorous 125% static/110% dynamic load testing, ISO 9001, CE. | Basic load tests, limited or no international certifications. |

| Ergonomics | Ergonomic handle, low-effort pump, quiet operation, diverse wheel options. | Basic handle, higher pumping effort, limited wheel choices. |

| Customization | Ability to customize fork dimensions, capacities, and special features. | Limited or no customization options. |

| After-Sales Support | Comprehensive warranty, readily available spare parts, responsive technical support. | Short warranty, difficulty sourcing parts, minimal support. |

A manufacturer's service history and global reach also speak volumes about their experience and authority. Companies with decades of experience serving clients in numerous countries often demonstrate a deeper understanding of diverse industry needs and regulatory requirements. This extensive experience translates directly into product reliability and customer satisfaction, essential factors for any business investment.

While standard models of hand pallet truck fulfill the majority of material handling needs, certain industries or unique operational environments demand tailored solutions. Leading hand pallet jack manufacturers recognize this and offer extensive customization options to meet precise client specifications. This capability is crucial for businesses dealing with non-standard pallet sizes, unique material compositions, or operating in specialized conditions such as corrosive environments, cleanrooms, or extremely narrow aisles.

Customization can range from:

This ability to provide bespoke solutions highlights a manufacturer's expertise and commitment to solving complex material handling challenges. It ensures that businesses don't have to compromise on efficiency or safety due to equipment limitations, leading to optimized workflows and improved return on investment. Collaborating with an experienced manufacturer for custom solutions leverages their technical know-how and design capabilities to create a truly fit-for-purpose tool.

Trustworthiness is a cornerstone when choosing hand pallet jack manufacturers. It’s built not just on product quality but also on the transparency of certifications, the robustness of warranty policies, and the efficiency of after-sales support. Reputable manufacturers will openly display their adherence to international quality and safety standards, providing tangible proof of their commitment to excellence.

Look for manufacturers who comply with or exceed standards such as:

These certifications provide a third-party validation of the manufacturer's processes and product safety, bolstering confidence in their offerings. Test data, such as load deflection tests or pump cycle tests (e.g., 20,000+ cycles for a robust hydraulic hand pallet truck), further substantiate claims of durability and performance.

Most manufacturers offer a standard delivery period, often between 2-4 weeks for standard models, with express options available for urgent needs. For custom orders, lead times may vary based on complexity. A robust warranty, typically 12-24 months for major components (like the hydraulic pump) and 6 months for wear parts (like wheels), signals the manufacturer's confidence in their product's durability. Comprehensive customer support, including easy access to spare parts and responsive technical assistance, ensures minimal downtime and a seamless ownership experience.

In a world increasingly driven by automation, the fundamental utility of a manual hand pallet truck remains undiminished. Its simplicity, reliability, and cost-effectiveness make it an indispensable asset for businesses of all sizes, from small enterprises to large-scale distribution networks. The dedication of leading hand pallet jack manufacturers to continuous improvement in design, material science, and manufacturing processes ensures that these tools continue to evolve, offering greater efficiency, enhanced safety, and extended operational lifespans. Investing in a high-quality hand pallet truck is not merely a purchase; it is an investment in operational resilience, workforce safety, and long-term productivity.

By prioritizing manufacturers who demonstrate expertise through rigorous testing, offer comprehensive support, and provide transparent product specifications, businesses can confidently equip their operations with the best material handling solutions available. The Hand Pallet Truck - CBY, as highlighted, serves as a testament to the quality and reliability that defines industry-leading products, ready to meet the demanding requirements of modern logistics.