Understanding the Working Principle of Chain Hoists

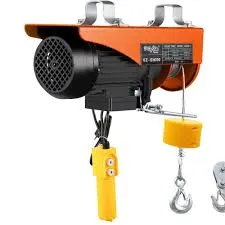

A chain hoist is an essential piece of equipment widely used in various industries for lifting heavy loads with ease and precision. Understanding the working principle of a chain hoist is crucial for both operators and maintenance personnel to ensure safety and efficiency in lifting operations.

At its core, a chain hoist consists of a few key components the chain, the hook, the gear system, and the lifting mechanism. The basic operation of a chain hoist is relatively simple, yet the intricacies of its design enable it to lift significant weights with minimal effort.

Components of a Chain Hoist

1. Chain The lifting element of the hoist, often made from steel, is responsible for transferring the load from one point to another. The chain is looped through a series of gears and is what the operator pulls to initiate lifting.

2. Hook The hook is the component that attaches the load to the hoist. It is designed to secure the load safely, and many hooks come equipped with safety latches to prevent accidental dislodgement.

3. Gear System This system is pivotal to the hoist's functionality. Inside the hoist, gears convert the manual pulling effort on the chain into a lifting motion. There are typically at least two gears the drive gear and the lifted gear. The ratio between these gears determines the mechanical advantage the operator gets, allowing them to lift heavier loads than they could with sheer force alone.

4. Lifting Mechanism The lifting mechanism usually consists of a brake system, which ensures that once the load is lifted, it remains securely in place until the operator is ready to lower it.

The Lifting Process

The operation of a chain hoist begins when the operator pulls down on the chain. This action rotates the drive gear, which in turn moves the lifted gear. As the lifted gear turns, it engages with the chain, causing it to move upward. The attached load moves with the chain due to the hook securely holding it in place.

The mechanical advantage provided by the gear system reduces the amount of effort needed to lift the load. For example, if the gear ratio is 41, pulling down on the chain with a force of 10 pounds could lift a load of 40 pounds. This features greatly enhance the efficiency of the lifting process, allowing a single operator to manage significantly heavier loads than would be possible with manual strength alone.

Safety Features

Safety is paramount in lifting operations, and chain hoists often come equipped with several safety mechanisms. Many modern hoists are fitted with overload protection, which automatically locks the hoist if a load exceeding its rated capacity is detected. This feature prevents potential damage to both the hoist and the load being lifted.

Additionally, the brake system plays a crucial role. It ensures that the load does not fall unexpectedly, which can lead to accidents and injuries. Regular inspections and maintenance of these safety features are essential to ensure their reliability.

Conclusion

In conclusion, understanding the working principle of a chain hoist is fundamental for efficient and safe lifting operations. With its simple yet effective mechanism of chains, gears, and hooks, a chain hoist enables operators to lift heavy loads with ease. Its design not only enhances productivity but also emphasizes safety, making it an invaluable tool in various industrial applications. Whether in construction, manufacturing, or warehouse operations, the chain hoist continues to be a vital component in the world of lifting and rigging.