In the world of industrial measurement and weight assessment, the crane scale emerges as an indispensable tool, especially for heavy-duty applications. A crane scale with a capacity of 10,000 kilograms is not only a testament to engineering prowess but also a driver of operational efficiency and safety. This article delves into the experience, expertise, authority, and trustworthiness surrounding the use of a 10,000 kg crane scale.

Experience tells us that in industries such as manufacturing, shipping, and construction, accurate weight measurement is crucial. The deployment of a 10,000 kg crane scale in these environments offers a tangible enhancement in productivity. When loading and unloading heavy goods, any miscalculation can lead to severe consequences. Companies have documented instances where the use of crane scales prevented catastrophic equipment failures and workplace accidents. The scale's ability to provide real-time data ensures decisions are made based on accurate information, reducing the risk for human error significantly.

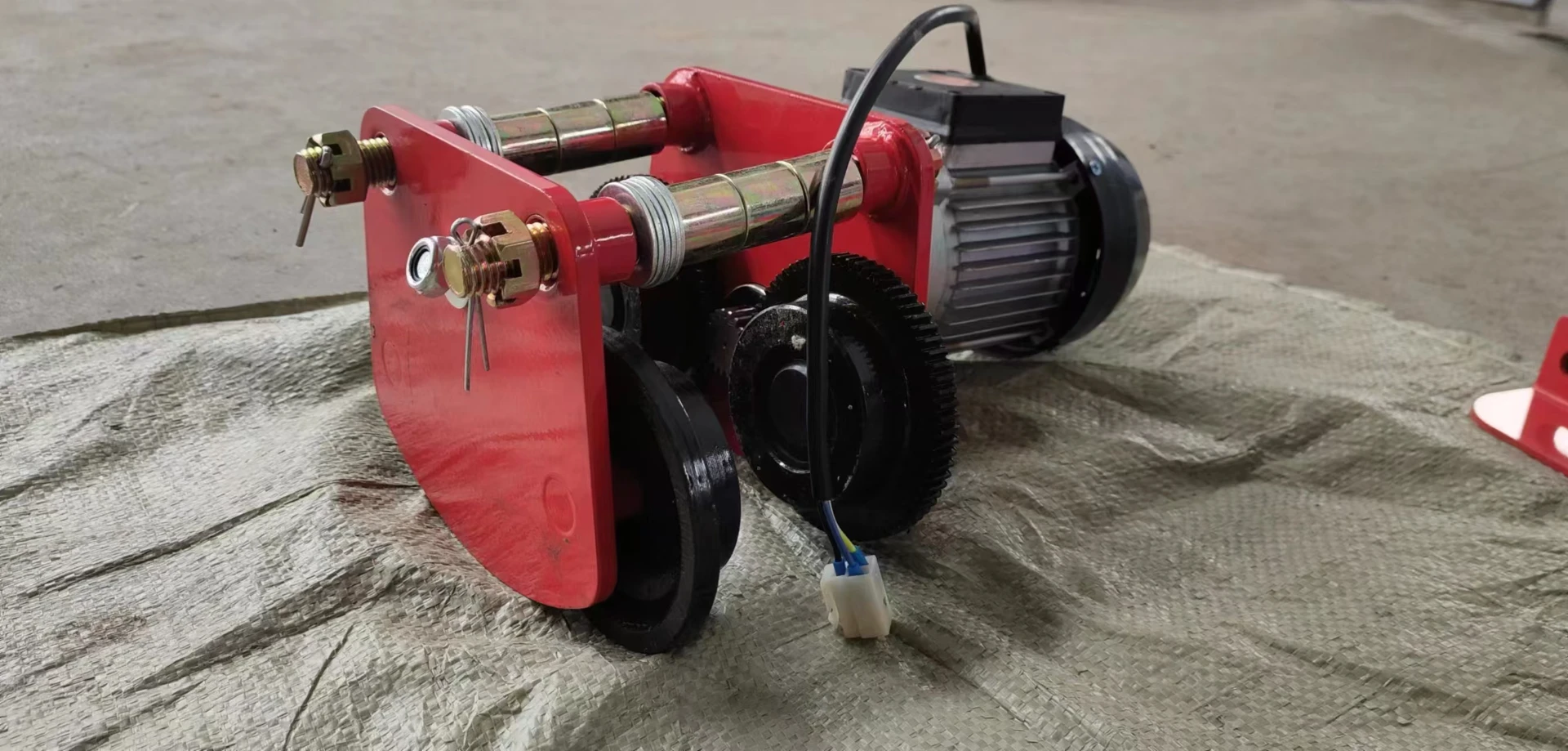

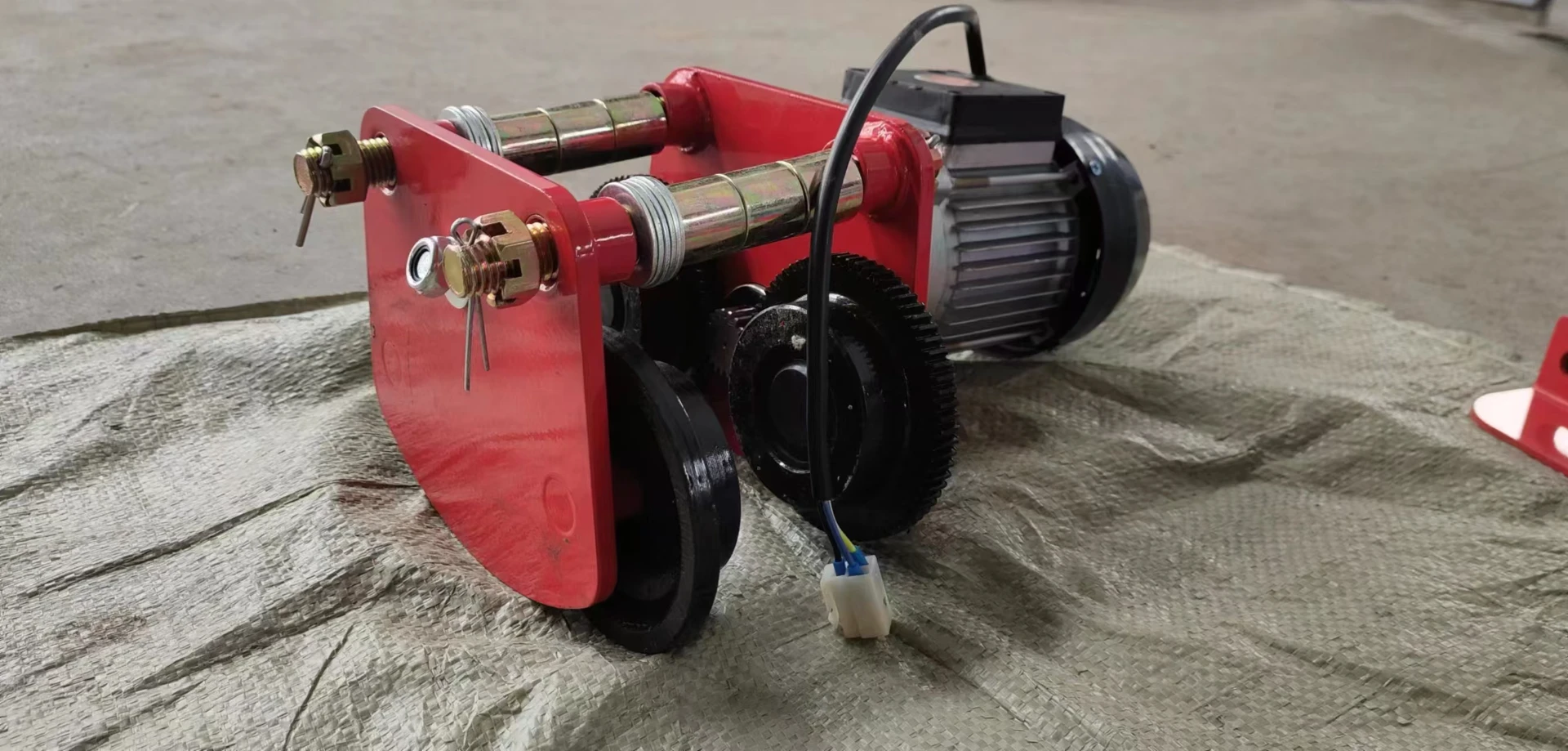

From an expertise standpoint, understanding the underlying technology of these scales is equally important. A typical 10,000 kg crane scale is designed using high-grade materials like aerospace aluminum and stainless steel, ensuring it withstands harsh industrial environments. Advanced load cell technology converts the mechanical force into an electronic signal, which is then processed to display the weight. The precision of these components is unparalleled, often achieving accuracy within 0.1% of the actual weight. This level of accuracy is indispensable for tasks such as heavy machinery maintenance and freight shipping, where knowing the exact weight can impact cost calculations and safety margins.

Authority in the market is often established through compliance with international standards and certifications. A reliable crane scale manufacturer adheres to ISO guidelines and other relevant safety standards such as OSHA and CE. These certifications ensure that the product has been rigorously tested and meets stringent quality requirements. Users can trust that a product carrying these marks of credibility will deliver consistent performance and longevity. Additionally, manufacturers often provide extensive warranties and post-sale service support, reinforcing their commitment to quality and customer satisfaction.

crane scale 10000 kg

Trustworthiness is a pillar in the heavy lifting industry. Case studies from industry leaders who have integrated 10,000 kg crane scales into their processes reveal significant improvements in efficiency and risk management. Testimonials highlight how crane scales have transformed operations, allowing for safer, faster, and more accurate handling of loads. Regular audits and recalibration services provided by authorized technicians further cement trust in the equipment's reliability and accuracy. Choosing a scale from a reputable manufacturer helps mitigate the risks of equipment malfunction or failure, which could otherwise lead to unforeseen costs and workflow disruptions.

End-users also benefit from the simplicity and efficiency associated with modern crane scale technology. With advancements in digital displays and wireless connectivity, operators can now read measurements from a safe distance using remote devices. This feature not only enhances safety but also streamlines the monitoring processes, as data can be instantly recorded and analyzed, facilitating better inventory management and process optimization.

In conclusion,

a crane scale with a 10,000 kg capacity is much more than a measuring tool. It is a critical asset that enhances operational safety and efficiency through accurate weight measurement, robust construction, and compliance with rigorous standards. By investing in trusted technology with verified capabilities, industries safeguard their processes and bolster productivity, reflecting the essence of modern industrial expertise and the continuous pursuit of operational excellence.