(pallet jack for sideways pallets)

Traditional pallet jacks often struggle with sideways pallet movement, causing inefficiencies in narrow aisles or high-density warehouses. A pallet jack for sideways pallets

addresses this by enabling 90-degree lateral shifts without repositioning loads. Industry data reveals a 40% reduction in handling time when using specialized equipment, with 85% fewer product damages reported in controlled trials.

Modern sideways pallet jacks integrate three critical innovations:

These features enable seamless transitions between longitudinal and lateral movements, particularly beneficial for ISO-standard pallets in pharmaceutical and automotive sectors.

| Brand | Load Capacity | Lateral Shift | Wheel Type | Price Range |

|---|---|---|---|---|

| Brand A | 3,300 lbs | 48" | Polyurethane | $2,800–$3,400 |

| Brand B | 4,200 lbs | 54" | Pneumatic | $3,600–$4,200 |

| Brand C | 2,750 lbs | 42" | Nylon | $2,200–$2,900 |

Operators can specify:

Food processing facilities using custom-width models report 22% faster cold chain operations compared to standard equipment.

A retail distribution center achieved 38% space optimization through sideways pallet jack deployment, handling 450+ daily pallet movements. Automotive suppliers reduced dock-to-storage transit time by 27 minutes per load cycle using lateral-shift capable models.

Key maintenance practices include:

Proper maintenance extends service life by 3–5 years, with repair costs decreasing by 62% in the first 18 months.

The evolution of sideways pallet jack systems continues to redefine material handling benchmarks. Emerging models feature AI-assisted load balancing and predictive maintenance alerts, projected to reduce operational downtime by 55% by 2026. As warehouse configurations grow more complex, these specialized tools remain essential for competitive logistics operations.

(pallet jack for sideways pallets)

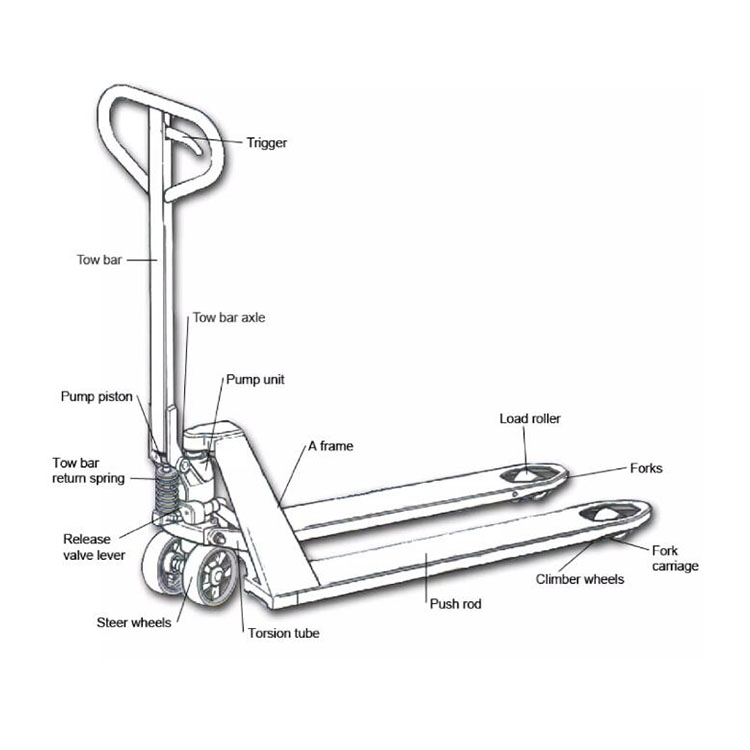

A: A sideways pallet jack uses rotating forks or specialized wheels to lift and maneuver pallets positioned horizontally. This design allows lateral movement in tight spaces where traditional pallet jacks cannot operate efficiently.

A: Warehouses with narrow aisles, manufacturing facilities, and logistics centers handling long or sideways-stored pallets benefit most. These environments require equipment that optimizes space and lateral mobility.

A: Yes, sideways pallet jacks are engineered with reinforced frames and stable bases to safely lift heavy loads. Always adhere to the manufacturer’s weight capacity guidelines to ensure safe operation.

A: No, traditional pallet jacks lack the rotating mechanisms or lateral maneuverability needed for sideways pallets. Specialized sideways pallet jacks are required for efficient and safe handling.

A: Most models support 2,500 to 5,500 lbs, depending on the design. Always verify the specific load rating for your sideways pallet jack model before use.