In the demanding landscape of industrial material handling, the selection of robust and reliable lifting equipment is paramount. The HSZ chain block, a cornerstone of mechanical lifting systems, stands out for its simplicity, durability, and exceptional operational safety across a myriad of applications. This critical piece of equipment is engineered to provide precise load control without requiring external power, making it an indispensable tool for operations in remote areas, hazardous environments, or where power supply is unreliable. Its widespread adoption spans from manufacturing and construction to maintenance and logistics, underscoring its versatility and enduring utility in facilitating heavy lifting tasks efficiently and securely. Understanding its inherent design principles, manufacturing precision, and versatile applications is key for any B2B decision-maker seeking optimal performance and safety.

The increasing demand for dependable manual hoisting solutions has driven significant advancements in the design and material science of chain blocks. Specifically, the HSZ type chain block has evolved to meet stringent industry standards, offering enhanced features such as improved gear efficiency, superior corrosion resistance, and ergonomic design for operator comfort. Modern HSZ units are designed not only for lifting but also for precise positioning, allowing for intricate adjustments of heavy loads. This comprehensive overview will delve into the core aspects that define the performance and reliability of these essential tools, guiding you through their technical nuances, manufacturing excellence, and strategic deployment in various industrial settings.

The reliability and longevity of an HSZ chain block are directly proportional to the rigor of its manufacturing process. High-quality production begins with the careful selection of premium materials, typically high-strength alloy steel for load chains (G80 or G100 grade) and robust carbon steel for critical components like gears, shafts, and hooks. The manufacturing journey of a premium hsz type chain block involves several sophisticated stages to ensure each unit meets exacting performance and safety criteria. Precision casting and forging techniques are employed for housing and structural components, providing superior mechanical properties and resistance to deformation under heavy loads. These initial processes lay the foundation for the block's structural integrity and operational stability.

Following the primary shaping, advanced CNC machining is extensively used to achieve the tight tolerances required for internal gearing and bearing surfaces. This precision machining minimizes friction, enhances efficiency, and prolongs the service life of the HSZ chain block. Heat treatment processes, such as quenching and tempering, are then applied to critical components to optimize their hardness, wear resistance, and toughness, ensuring they can withstand repetitive stress and heavy loads over extended periods. Surface treatments, including anti-corrosion coatings or galvanization, are often applied, especially for models destined for harsh or corrosive environments like offshore platforms or chemical processing plants. This meticulous layering of processes ensures the final product delivers consistent, reliable performance throughout its operational lifespan.

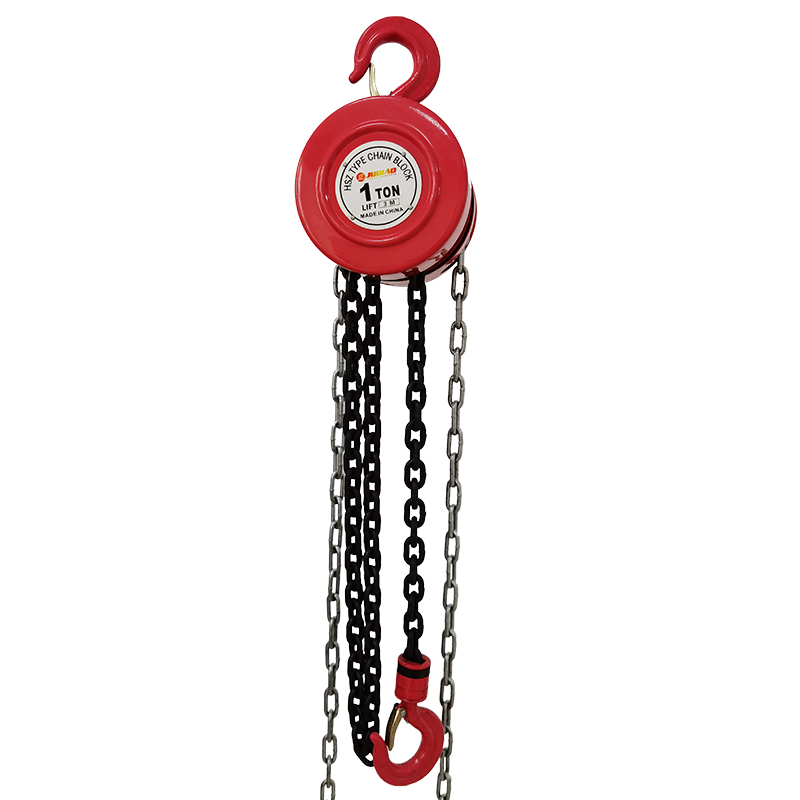

Figure 1: Illustrative manufacturing process for HSZ Chain Blocks, emphasizing material quality and precision engineering.

Quality control is integrated at every stage, from raw material inspection to final product testing. Each hsz chain block undergoes rigorous testing protocols, including proof load tests (typically 150% of rated capacity), operational tests, and fatigue tests, to comply with international standards such as ISO 9001, ANSI/ASME B30.16, and EN 13157. These stringent checks guarantee that the product delivers not only on its rated capacity but also on safety and durability. For industries such as petrochemical, metallurgy, and water treatment, the anti-corrosion properties and energy-efficient design of modern hsz type chain block models provide significant advantages, ensuring operational integrity in challenging conditions while contributing to lower operational costs through reduced maintenance and enhanced performance.

Understanding the technical specifications of an HSZ chain block is crucial for its correct selection and safe operation. Key parameters include rated lifting capacity, standard lifting height, test load, minimum headroom, and the number of load chain falls. These specifications directly impact the block's suitability for specific applications and its overall operational efficiency. Modern hsz type chain block designs often feature triple-spur geared mechanisms and robust braking systems, such as dual-pawl load brakes, to ensure secure load holding and precise control during lifting and lowering operations. The design emphasizes a compact structure for easier integration into various setups, even in confined spaces, while maintaining high mechanical efficiency, typically ranging from 80% to 90%.

| Parameter | HSZ-0.5T | HSZ-1T (HSZ type chain block 1 ton) | HSZ-2T | HSZ-3T |

|---|---|---|---|---|

| Rated Capacity (Ton) | 0.5 | 1.0 | 2.0 | 3.0 |

| Standard Lift (m) | 3 | 3 | 3 | 3 |

| Test Load (Ton) | 0.75 | 1.5 | 3.0 | 4.5 |

| Minimum Headroom (mm) | 260 | 300 | 350 | 400 |

| Number of Load Chain Falls | 1 | 1 | 1 | 1 |

| Load Chain Diameter (mm) | 6 | 6 | 8 | 10 |

| Net Weight (kg) | 8.5 | 11.5 | 19.5 | 28 |

These parameters are critical for engineers and procurement managers to ensure compatibility with existing infrastructure and to meet specific project requirements. For instance, when considering an hsz type chain block 1 ton, the minimum headroom dictates its usability in spaces with height restrictions, while the load chain diameter indicates the robustness and safety factor of the lifting mechanism. Understanding these detailed technical aspects ensures that the chosen HSZ chain block will perform optimally and safely within its intended operational environment, contributing to improved project efficiency and reduced operational risks. Modern HSZ units are also designed with a lower pulling force requirement on the hand chain, minimizing operator fatigue and boosting productivity, a key consideration for manual operations.

The adaptability of the HSZ chain block makes it a staple across a diverse range of industries. In the construction sector, it is invaluable for lifting steel beams, concrete slabs, and heavy machinery components on job sites where electricity is not readily available. For manufacturing facilities, HSZ chain blocks are commonly used on production lines for assembly, maintenance, and tool & die changes, offering precise positioning capabilities. The petrochemical industry relies on explosion-proof or corrosion-resistant variants of the hsz type chain block for maintenance in hazardous areas, ensuring safe handling of valves, pumps, and pipe sections. Furthermore, in shipyards and marine environments, their robust construction and resistance to saline conditions make them ideal for rigging, engine maintenance, and cargo handling operations. The simplicity and manual operation inherent in their design eliminate the risks associated with electrical failures, providing an intrinsic layer of operational safety.

Figure 2: HSZ Chain Block in operation, demonstrating its utility in a typical industrial setting.

The technical advantages of the HSZ chain block extend beyond its basic lifting function. Its compact design and relatively light weight (for its capacity) facilitate easy transport and installation, especially for the hsz type chain block 1 ton model, making it highly portable for on-site applications. The precision gearing system ensures smooth and controlled lifting and lowering, minimizing shock loads and enhancing the safety of both personnel and equipment. Equipped with robust safety features, including overload protection mechanisms and high-strength hooks with safety latches, the HSZ series prioritizes operator well-being. Furthermore, their low maintenance requirements and exceptional durability translate into a lower total cost of ownership over the product's lifespan, offering a significant economic advantage for businesses prioritizing long-term value and operational reliability.

The market for chain blocks is continually evolving, driven by demands for greater efficiency, enhanced safety features, and specialized applications. Current industry trends highlight a shift towards more ergonomic designs, advanced materials for increased corrosion resistance, and integration of smart features, even in manual systems, such as improved load indicators or enhanced braking systems. While the fundamental mechanics of the HSZ chain block remain consistent, leading manufacturers are differentiating themselves through superior material quality, stricter adherence to international standards (e.g., DIN, JIS), and innovative design elements that reduce operator effort and increase hoist speeds. When comparing manufacturers, it's vital to assess their track record, certifications (ISO 9001, CE), and the availability of comprehensive after-sales support and spare parts. A reputable manufacturer will often provide extensive technical documentation and transparent testing results, building trust and ensuring long-term product reliability.

Beyond standard models, bespoke custom solutions are increasingly sought after to address unique industrial challenges. This includes hsz type chain block units designed for exceptionally high lifts, specific environmental conditions (e.g., extremely low temperatures, high humidity, or explosive atmospheres), or integrated into complex rigging systems. Customization options might involve specialized chain lengths, non-standard capacities, stainless steel components for hygienic or highly corrosive environments, or particular hook designs for unique lifting points. Engaging with a manufacturer capable of providing engineered-to-order solutions ensures that the HSZ chain block perfectly aligns with the operational nuances of a specific project, maximizing efficiency and mitigating risks associated with off-the-shelf equipment that doesn't fully meet requirements. These tailored solutions underscore the flexibility and adaptability of the HSZ design when partnered with an expert supplier.

Figure 3: HSZ Chain Block customized for specialized industrial applications.

For instance, a client in the renewable energy sector required a lightweight yet robust hsz type chain block 1 ton for maintenance tasks on wind turbines, necessitating specific anti-corrosion treatments and a compact design for elevated, tight spaces. Another case involved a waste-water treatment plant needing several HSZ chain block units with full stainless-steel construction to resist highly corrosive chemical vapors, a standard product would not suffice. These examples highlight the critical role of custom engineering in meeting advanced industrial demands, ensuring peak performance and extended operational life in challenging or unique conditions. Partnering with a manufacturer offering comprehensive customization and engineering support is therefore a strategic decision for B2B clients seeking optimal lifting solutions.

A: With proper maintenance and adherence to rated capacities, an HSZ chain block can provide reliable service for 10-15 years or more. Regular inspection of chains, hooks, and braking mechanisms is crucial for extending its operational life. High-quality materials and manufacturing significantly contribute to this longevity.

A: Yes, standard HSZ chain blocks can be used outdoors, but for prolonged exposure to harsh weather or corrosive environments, it's recommended to opt for models with enhanced anti-corrosion coatings or stainless steel components. Proper storage after use is also advised to prevent rust and extend product life.

A: Routine maintenance includes checking the load chain for wear, deformation, or corrosion; inspecting hooks for bending or cracks; verifying the brake's effectiveness; and ensuring smooth operation of the hand chain and gears. Lubrication of internal components as per manufacturer guidelines is also essential. Annual professional inspections are highly recommended.

We understand the critical importance of timely delivery for industrial projects. Standard HSZ chain block models are typically dispatched within 3-5 business days upon order confirmation, subject to stock availability. For large volume orders or specialized hsz type chain block configurations, lead times will be confirmed during the quotation process, generally ranging from 2-4 weeks. We leverage a robust global logistics network to ensure efficient and secure delivery to your specified location, complete with tracking and comprehensive customs documentation support for international shipments. Our logistics partners are selected based on their proven reliability and ability to handle industrial equipment with care, minimizing transit damage and delays.

Every HSZ chain block purchased comes with a standard 12-month manufacturer's warranty, covering defects in materials and workmanship from the date of purchase. Extended warranty options are available for specific projects or high-usage environments. Our dedicated after-sales support team is readily available to provide technical assistance, troubleshooting, and guidance on maintenance and spare parts. We maintain a comprehensive inventory of genuine replacement parts to ensure rapid repair and minimal downtime for your operations. Our commitment to customer satisfaction extends beyond the point of sale, providing partners with peace of mind and ensuring the long-term, reliable performance of your lifting equipment. This holistic approach reinforces our dedication to trustworthiness and product performance.