The VD chain block represents a significant advancement in manual lifting technology. Designed for versatility and durability, this chain hoist block is engineered to meet the demands of various industrial applications. Its compact design, enhanced structural integrity, and improved operational efficiency make it a preferred choice for professionals in construction, manufacturing, and logistics. This article delves into the manual chain hoist's features, specifications, and real-world applications, supported by authoritative insights from the National Institute of Standards and Technology (NIST).

The VD chain block is an upgraded chain hoist block, incorporating advanced engineering principles to deliver superior performance. Its lightweight construction and streamlined design ensure ease of use, while high-quality materials guarantee long-term reliability. The product is particularly suited for environments where portability and precision are critical, such as open-air operations and settings without a power supply.

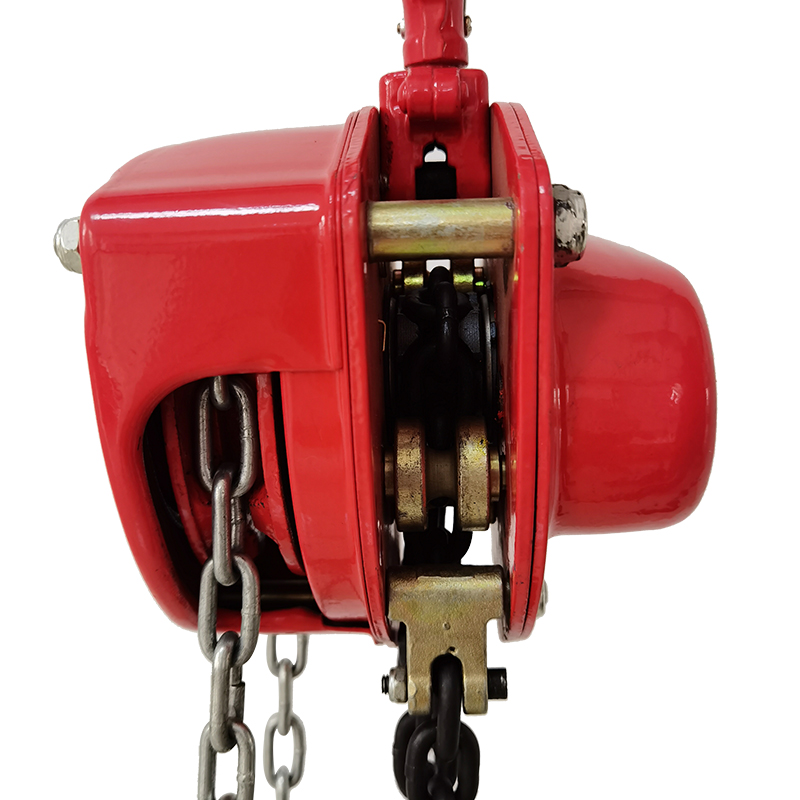

The VD chain block features a double brake structure, ensuring precise locking positions and effective stall control. This design enhances safety by maintaining stability during lifting operations, providing users with greater peace of mind.

The reinforced triangular cover is made from thickened alloy steel, offering resistance to collisions and corrosion. This innovation significantly extends the product's service life, even in harsh environments.

The enlarged guide sprocket, combined with a smooth bearing system, minimizes resistance and prevents chain jamming. This design ensures seamless operation and reduces maintenance requirements.

By replacing traditional gear friction with a three-in-one bearing system, the VD chain block improves rotation efficiency and durability. This advancement results in smoother lifting performance and longer operational lifespan.

The pawl, crafted from high-strength manganese steel, is engineered to withstand wear and tear. After quenching, it achieves enhanced toughness, ensuring reliable operation under heavy loads.

The hook is quenched and refined with an anti-removal lock mechanism, making it robust and durable. This feature prevents accidental disengagement, further enhancing user safety.

The VD chain block is available in multiple models, each tailored to specific lifting requirements. The following table outlines the key parameters:

| Model | VD-0.5 | VD-1 | VD-1.5 | VD-2 | VD-3 | VD-5 | VD-10 | VD-20 |

|---|---|---|---|---|---|---|---|---|

| Capacity (t) | 0.5 | 1 | 1.5 | 2 | 3 | 5 | 10 | 20 |

| Standard Lifting Height (m) | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3 | 3 |

| Test Load Capacity (t) | 0.75 | 1.25 | 2.25 | 3 | 4.5 | 7.5 | 12.5 | 25 |

| Pulling Force to Lift Full Load (N) | 262 | 324 | 395 | 330 | 402 | 430 | 438 | 438 |

| No. of Load Chain Lines | 1 | 1 | 1 | 1 | 1 | 2 | 4 | 8 |

| Diameter of Load Chain (mm) | 5 | 6 | 7 | 8 | 10 | 10 | 10 | 10 |

| Net Weight (kg) | 9.3 | 12.2 | 16.5 | 19.5 | 32 | 43 | 80.7 | 180 |

| Extra Weight per Meter (kg) | 1.5 | 1.8 | 2 | 2.7 | 3.2 | 5.3 | 9.8 | 19.6 |

The VD chain block is designed for a wide range of applications, including but not limited to:

According to the National Institute of Standards and Technology (NIST), the integration of precision-engineered lifting tools like the VD chain block is critical for ensuring safety and operational efficiency in industrial settings [1].

The VD chain block is manufactured by Qingyuan Juli Hoisting Machinery Co., Ltd., a reputable company specializing in lifting equipment. With a commitment to quality and innovation, the company has established itself as a leader in the industry. Their products are designed to meet international standards, ensuring reliability and performance in diverse environments.

The VD chain block exemplifies the synergy of advanced engineering and practical design, offering a robust solution for manual lifting needs. Its comprehensive features, supported by rigorous technical specifications, make it a versatile tool across various industries. As highlighted by NIST's research on industrial safety standards, the adoption of such high-quality equipment is essential for maintaining operational excellence and worker safety [1].