Introduction to Advanced Hoisting Solutions

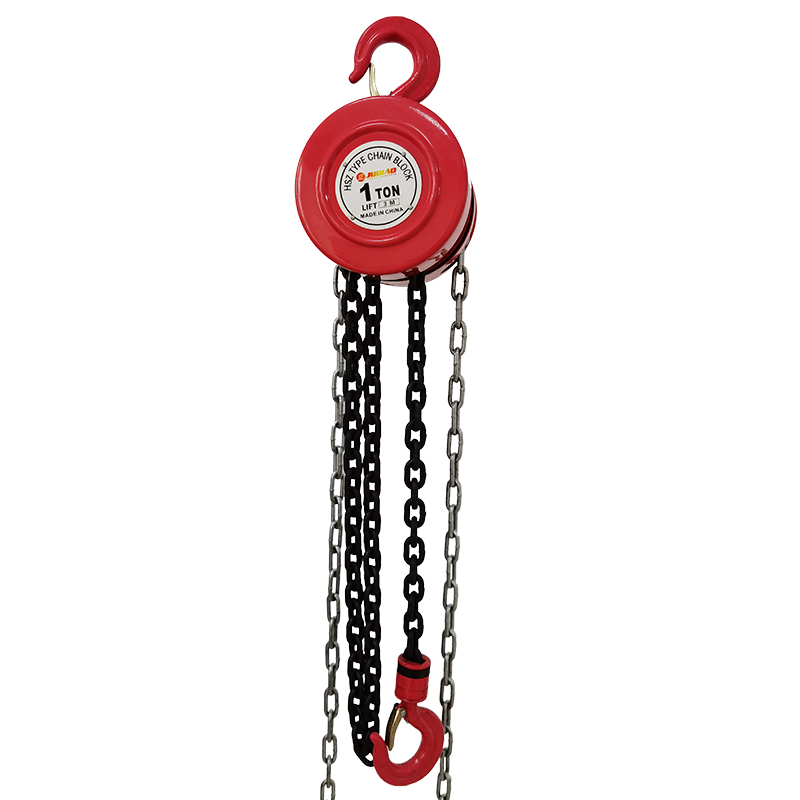

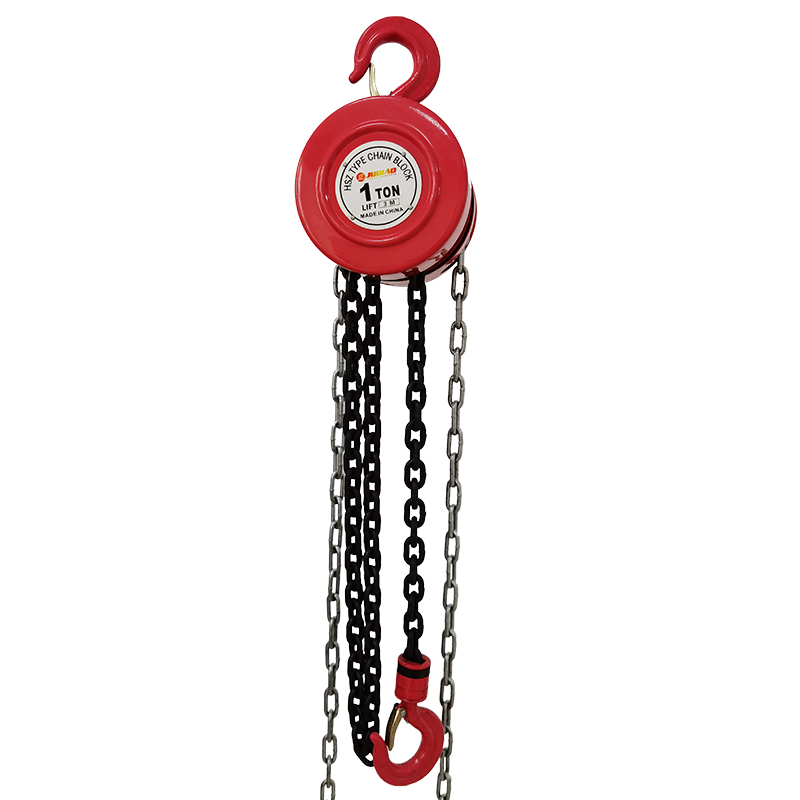

In industrial material handling, efficiency, safety, and durability are paramount. The hsz chain block stands as a testament to these principles, offering robust and reliable manual lifting capabilities essential across diverse sectors. Engineered for demanding environments, this mechanical hoisting device utilizes a hand chain to lift heavy loads, providing a cost-effective and portable solution where power sources are unavailable or impractical. Its design emphasizes ergonomic operation, minimal maintenance, and extended service life, making it a critical asset for precise load positioning and controlled lifting operations.

Our focus delves into the comprehensive aspects of the hsz chain block, covering its sophisticated manufacturing process, adherence to international quality standards, critical technical specifications, and broad application spectrum. We aim to provide B2B decision-makers and engineers with an authoritative resource that underscores the value proposition of this essential lifting equipment.

Precision Manufacturing Process of the HSZ Chain Block

The superior performance of the hsz chain block begins with a meticulously controlled manufacturing process, adhering to stringent quality control standards such as ISO 9001:2015. This multi-stage process ensures each component meets precise specifications for strength, durability, and operational safety.

Schematic Process Flow:

-

Material Selection & Sourcing: High-grade alloy steel (e.g., G80 for load chains, 20CrMnTi for gears) is rigorously selected from certified suppliers. Materials undergo spectrographic analysis to confirm metallurgical composition and absence of defects.

-

Forging & Casting: Critical components like the hook, gear housing, and hand chain wheel are forged or cast. Forging for hooks enhances grain structure, improving fatigue resistance and tensile strength. Casting provides robust, intricate shapes for housings.

-

CNC Machining: Precision machining on CNC centers shapes gears, shafts, and other internal components to exceptionally tight tolerances (e.g., micron-level accuracy for gear teeth). This ensures smooth operation, minimal backlash, and extended service life.

-

Heat Treatment: Components such as load chains, gears, and pawls undergo specialized heat treatment processes (e.g., carburizing, quenching, tempering). This enhances surface hardness, core toughness, and wear resistance, significantly extending component lifespan under heavy loads.

-

Surface Treatment: Corrosion resistance is critical for applications in harsh environments. Components receive various surface treatments, including electro-galvanization, powder coating, or specialized anti-corrosion paints. For example, some models feature chrome-plated hooks and a durable epoxy powder-coated finish for petrochemical or marine use.

-

Assembly: Skilled technicians assemble the meticulously manufactured components, ensuring correct alignment and lubrication. Each assembly step follows detailed work instructions to maintain consistency.

-

Testing & Quality Control:

-

Proof Load Testing: Every hsz type chain block is individually proof-load tested at 1.5 times its Rated Capacity (RC) in accordance with EN 13157 and ASME B30.16 standards.

-

Operational Performance Testing: Tests include brake functionality, chain movement smoothness, and overall mechanical efficiency under various loads.

-

Dimensional Inspection: Verification of all critical dimensions and tolerances.

-

Non-Destructive Testing (NDT): Ultrasonic or magnetic particle inspection for critical welds and forgings.

-

Final Inspection & Certification: Each unit is inspected, marked with its serial number, and certified, ensuring full traceability and compliance.

The typical service life of an hsz chain block, when properly maintained and operated within its rated capacity, exceeds 10 years, with critical components designed for a fatigue life of over 20,000 cycles at rated capacity. Advantages include energy saving through high mechanical efficiency (often >85%), and robust corrosion resistance due to advanced surface treatments, vital for industries like petrochemicals and water treatment.

Illustration: Internal mechanism of an HSZ chain block, showcasing precision engineering.

Industry Trends and Market Dynamics for Chain Blocks

The market for manual lifting equipment, particularly the hsz type chain block, is experiencing several significant trends. Automation in material handling is rising, but there remains an indispensable demand for versatile, non-powered solutions for specific applications.

-

Enhanced Safety Features: Manufacturers are integrating advanced safety features, such as double pawl braking systems, overload protection devices, and improved hook designs with robust safety latches, to meet increasingly stringent global safety standards (e.g., ASME B30.16, EN 13157).

-

Material Innovation: The use of lighter, stronger alloy steels and specialized coatings is leading to more compact, corrosion-resistant, and durable chain blocks, expanding their utility in offshore, chemical, and pharmaceutical industries.

-

Ergonomics and User Comfort: Designs are evolving to reduce operator fatigue, incorporating smoother hand chain pulls, optimized gear ratios, and more comfortable grip designs for the hand chain.

-

Digital Integration (Limited but Growing): While predominantly mechanical, some high-end units are starting to incorporate smart features like RFID for asset tracking or integrated load cells for real-time weight monitoring, particularly in critical lifting operations.

-

Sustainability Focus: Demand for products with longer service life, easier maintenance, and recyclable components is growing, aligning with broader industrial sustainability goals.

The global material handling equipment market is projected to grow at a CAGR of over 7% through 2028, with manual lifting devices maintaining a crucial segment due to their cost-effectiveness and adaptability. This sustained demand underlines the strategic importance of reliable equipment like the hsz chain block.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of an hsz chain block is critical for optimal selection and safe operation. These parameters dictate the suitability of the block for various lifting tasks and environments.

Key Specifications for HSZ Chain Blocks (Typical Model Example):

| Parameter |

HSZ Type Chain Block (1 Ton) |

HSZ Type Chain Block (3 Ton) |

HSZ Type Chain Block (5 Ton) |

| Rated Capacity (RC) |

1 Ton (1000 kg) |

3 Ton (3000 kg) |

5 Ton (5000 kg) |

| Standard Lifting Height |

3 meters |

3 meters |

3 meters |

| Load Chain Diameter |

6 mm (G80) |

8 mm (G80) |

10 mm (G80) |

| Number of Load Chain Falls |

1 |

1 |

2 |

| Pulling Force (Rated) |

280 N |

350 N |

380 N |

| Gear Ratio |

1:25 |

1:35 |

1:45 |

| Minimum Head Room |

280 mm |

380 mm |

520 mm |

| Net Weight (3m lift) |

10 kg |

25 kg |

38 kg |

| Safety Factor |

4:1 or 5:1 (RC) |

4:1 or 5:1 (RC) |

4:1 or 5:1 (RC) |

| Operating Temperature |

-20°C to +40°C |

-20°C to +40°C |

-20°C to +40°C |

| Certifications |

CE, ISO 9001, TUV |

CE, ISO 9001, TUV |

CE, ISO 9001, TUV |

These specifications highlight the robust engineering behind each hsz type chain block 1 ton, 3 ton, or 5 ton unit, ensuring high performance and safety in diverse lifting operations. Minimum headroom, for example, is a critical parameter for applications in confined spaces.

Versatile Application Scenarios

The adaptability of the hsz chain block makes it an invaluable tool across a multitude of industries. Its independence from external power sources offers unparalleled flexibility for on-site operations, maintenance, and emergency lifting.

-

Construction & Infrastructure: Ideal for lifting construction materials, positioning structural components, or raising heavy equipment in areas without electrical access. Its portability allows for rapid deployment on job sites.

-

Manufacturing & Assembly Plants: Used for precise placement of machinery parts, engine components, or sub-assemblies. The controlled lifting and lowering speed is crucial for delicate operations.

-

Shipbuilding & Marine: Essential for maintenance tasks on vessels, lifting components in dry docks, or emergency repairs in remote marine environments where corrosion resistance is key.

-

Mining & Metallurgy: Employed in underground mining for equipment positioning, ventilation system maintenance, or in metallurgical plants for handling raw materials and processed metals.

-

Petrochemical & Energy: In hazardous environments, non-sparking hsz type chain block versions are crucial for maintaining pumps, valves, and other critical infrastructure, reducing the risk of ignition. Corrosion-resistant models are vital for chemical processing plants.

-

Water Supply & Drainage: For installing and maintaining large pumps, pipes, and control gate mechanisms in water treatment plants and pumping stations.

-

Warehousing & Logistics: Used for loading/unloading heavy items from trucks or positioning goods within warehouses, especially for items that require precise handling or are too heavy for forklifts in certain areas.

Image: HSZ chain block in an industrial setting, demonstrating practical application.

Technical Advantages of HSZ Chain Blocks

The design and engineering of the hsz chain block provide distinct technical advantages that set it apart in the manual lifting category. These attributes contribute directly to operational efficiency, safety, and longevity.

-

High Mechanical Efficiency: Achieved through precision-machined gears, sealed bearings, and optimized gear ratios, minimizing the effort required by the operator. Typical efficiency can exceed 85%, significantly reducing manual labor and fatigue.

-

Robust Braking System: Equipped with a dual-pawl, Weston-style brake mechanism that holds the load securely at any position. This auto-locking feature ensures maximum safety during lifting and lowering, preventing accidental load descent.

-

Superior Load Chain Quality: Utilizes heat-treated, alloy steel G80 load chains, providing exceptional tensile strength, wear resistance, and corrosion protection. Each chain link is precisely calibrated for smooth engagement with the load wheel.

-

Compact Design and Low Headroom: Engineered for minimal physical footprint, allowing operations in confined spaces where larger, powered hoists cannot be deployed. This is crucial in facilities with limited overhead clearance.

-

Durability and Corrosion Resistance: Housings typically feature robust steel construction with high-quality powder coating or specialized anti-corrosion finishes. Internal components are often nickel or zinc-plated to resist rust, extending product life in aggressive environments.

-

Ease of Maintenance: Simple, modular construction facilitates easy inspection and component replacement, minimizing downtime and extending the economic life of the equipment. Fully enclosed gearboxes protect internal mechanisms from dust and moisture.

Vendor Comparison: Evaluating HSZ Chain Block Suppliers

Selecting the right vendor for an hsz chain block involves more than just price; it requires a deep understanding of product quality, compliance, support, and customization capabilities. Below is a comparative overview demonstrating critical differentiators.

| Feature/Criteria |

QY JULI (Our Standard) |

Competitor A (Premium) |

Competitor B (Economy) |

| Load Chain Material |

G80 High-Tensile Alloy Steel |

G100 Ultra-High Tensile Alloy Steel |

G70 Standard Alloy Steel |

| Brake System |

Dual-Pawl Weston Brake (Asbestos-free) |

Dual-Pawl with Overload Limiter |

Single-Pawl Friction Brake |

| Corrosion Resistance |

Powder-coated housing, Zinc-plated internal |

Marine-grade coating, Stainless steel options |

Basic paint finish |

| Certifications |

CE, ISO 9001, TUV |

CE, ATEX, DNV GL, ISO 9001 |

Basic CE |

| Warranty Period |

1-Year Standard |

2-5 Years (Extended Options) |

6 Months |

| Customization Options |

Chain length, Hook types, Special coatings |

Extensive: ATEX, Cleanroom, Custom capacity |

Limited: Chain length only |

QY JULI emphasizes a balance of high-quality components, adherence to essential safety standards, and robust performance, positioning our hsz type chain block as a reliable and cost-effective solution for industrial applications. Our focus is on providing durable, safe equipment that meets international benchmarks without unnecessary premium overheads.

Customized Solutions for Specific Industrial Needs

Recognizing that standard products may not always meet unique operational challenges, we offer tailored customization for the hsz chain block to address specific client requirements.

-

Extended Load & Hand Chain Lengths: For applications requiring lifting beyond standard heights, custom chain lengths are available.

-

Specialized Hooks: Options include larger throat openings, swivel hooks with bearings, or bronze hooks for non-sparking requirements in hazardous environments.

-

Corrosion-Resistant Variants: For marine, chemical, or pharmaceutical industries, units can be supplied with stainless steel components, advanced epoxy coatings, or food-grade lubricants.

-

Overload Protection: Integrated slip clutches or shear pins can be incorporated to prevent accidental overloading, safeguarding both equipment and personnel.

-

Cleanroom Compatibility: For sensitive environments, chain blocks can be manufactured with specialized lubricants, sealed mechanisms, and non-particle-shedding coatings to meet cleanroom standards (e.g., ISO Class 7).

Our engineering team collaborates closely with clients to develop solutions that optimize performance and safety for their specific operational contexts.

Application Case Studies and Client Success

Real-world deployments demonstrate the reliability and effectiveness of the hsz chain block. Our client partnerships highlight successful implementation and the tangible benefits derived from our products.

Case Study 1: Petrochemical Plant Maintenance

A major petrochemical complex required a non-sparking, corrosion-resistant lifting solution for routine valve and pump maintenance in an ATEX Zone 1 environment. Standard electric hoists were unsuitable due to ignition risks. We supplied custom hsz type chain block 1 ton units with bronze hooks, stainless steel load chains, and specialized anti-corrosion coatings. The client reported a significant reduction in maintenance downtime and enhanced worker safety, with the blocks performing flawlessly over three years without requiring major component replacement.

Case Study 2: Remote Construction Site Equipment Installation

For a remote hydropower project, heavy generators and turbines needed to be precisely positioned within an unfinished structure lacking grid power. We provided a series of 5-ton hsz chain block units with extended lifting heights. Their portability and robust design enabled the construction crew to handle components weighing up to 4.5 tons with accuracy and safety, circumventing the need for expensive, temporary power installations or large mobile cranes. The project manager praised the reliability and ease of use in challenging conditions.

Detail: The robust construction and components of the HSZ chain block.

Frequently Asked Questions (FAQ)

-

Q: What is the maximum lifting capacity for a standard hsz chain block?

A: Standard models range from 0.5 tons up to 20 tons. Specialized heavy-duty versions can exceed this.

-

Q: What is the typical lead time for an hsz type chain block order?

A: For standard configurations, lead time is typically 5-10 business days. Custom orders may require 3-4 weeks, depending on complexity and material availability.

-

Q: Is it safe to operate an hsz type chain block 1 ton beyond its rated capacity?

A: Absolutely not. Operating any chain block beyond its Rated Capacity (RC) is extremely dangerous and can lead to catastrophic equipment failure, severe injury, or death. Always adhere strictly to the stated RC and safety factors.

-

Q: What kind of warranty do you offer?

A: We offer a standard 1-year warranty on all hsz chain block products, covering defects in materials and workmanship. Extended warranty options are available upon request.

-

Q: How do I get technical support or after-sales service?

A: Our dedicated customer support team is available via phone, email, and live chat during business hours. We provide technical guidance, spare parts, and troubleshooting assistance. On-site service can also be arranged for complex issues.

Ordering, Fulfillment, and Support

We streamline the procurement process to ensure timely delivery and robust after-sales support for every hsz chain block.

Lead Time & Fulfillment:

Our efficient manufacturing and logistics networks ensure prompt order fulfillment. Standard hsz chain block models are typically dispatched within 5-10 business days. For customized solutions or large-volume orders, a project-specific lead time will be provided, generally ranging from 3 to 4 weeks. We offer various shipping options, including express and freight, to meet specific project timelines globally.

Warranty Commitments:

Each QY JULI hsz chain block is backed by a comprehensive 1-year limited warranty against manufacturing defects in materials and workmanship from the date of purchase. This commitment reflects our confidence in the quality and durability of our products, ensuring peace of mind for our clients. Full warranty terms and conditions are available upon request.

Customer Support & After-Sales Service:

Our dedication extends beyond the sale. QY JULI provides expert technical support and comprehensive after-sales service. Our team of certified professionals is available to assist with product selection, installation guidance, troubleshooting, and maintenance advice. We maintain an extensive inventory of genuine spare parts to facilitate quick repairs and minimize operational downtime. For direct assistance, please contact us via our website, email, or dedicated service hotline.

Conclusion

The hsz chain block remains a cornerstone in manual material handling, offering an unparalleled combination of reliability, safety, and versatility. Its robust construction, adherence to international safety standards, and adaptability to diverse industrial environments make it an indispensable asset for businesses seeking efficient and secure lifting solutions. By investing in high-quality, meticulously engineered chain blocks, industries can ensure operational continuity, enhance worker safety, and achieve long-term cost efficiencies.

References

- ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization.

- ASME B30.16-2022 - Overhead Hoists (Underhung). American Society of Mechanical Engineers.

- EN 13157:2004+A1:2009 - Cranes — Safety — Hand powered lifting equipment. European Committee for Standardization.

- "Global Material Handling Equipment Market: Industry Analysis & Forecast (2023-2028)." Maximize Market Research.